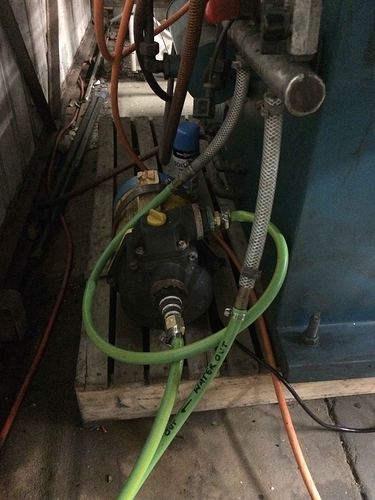

Myself and @ben started working on the cooling system, I bought some garden hosing and used some blue barrels from the boneyard to make the basic shape. The pump we got initially was way to weak for the job but Ben came across a much larger old one he reconditioned to work with the molder.

Next up we will need some corrugated plastic sheeting, I spotted these beside a container does anyone have any info on them? they would work great if they are waste and can be recycled to work in the cooling system

This was donated by @roving on discord, I think it was destined to stay roofing for space stuff but send them a bell and see what they think

Cool thanks il have a check with him

Ok so the hopper is finished thanks to @lincolnbphillips001 it turned out really well and adds a workable 5 litres or so of plastic to the machine.

The pump was strapped down, plumed up and tested. It all works great however a little leaky!

Thanks for @Ben for his help on that

The cooling tower is basically finished now, thanks to @roving for supplying the plastic sheeting. Some of the corrugated sheeting was chopped and placed at angles to eachother. Water is then dripped ontop of this, where it slowly runs down the corrugations into the

into the tank, the fan sucks air up from the bottom colling the water as it trickles down the corrugations. The is the exact same principle used in industrial chillers for injection molding.

Ghetto as - love it!

Cheers Drew

Just more info for everyone interested in plastics, injection molding and recycling

The map of others building injection molders and equipment for processing plastic.

Im keen to try recycled materials in the machine once there processed correctly and are clean this might involve costic cleaning or something.

At the moment i need to figure out how I can get the pockets cut into the mold, require carbide bits that I dont have at the moment if anyone has any help on this send me a message

I am also very interested in getting back in contact with a guy I was talking to at the injection molding machine one Tuesday evening. He had a lot of knowledge about biodegradable plastics and I think was based in UQ or QUT? If anyone knows him send on the contact.

I have only just attended on open night and know very little about injection moulding after seeing Precious Plastic on youtube https://youtu.be/VFIPXgrk7u0 recently I was pleasantly surprised to see an injection moulder at hsbne. I would definitely like to get involved in this project.

Cheers David

Hey I should be down there from 7pm onward tomorrow if you would like to have a chat

Hi Alan, I will be there for Induction at 6pm so look forward to meeting you and having a chat then. Cheers David

Nice meeting you David, great to have you onboard as i said jump in where ever you think you can help!

So the hold up in molding is due to there not being enough people trained in on Hulk to cnc the pocket. Once the pocket is done there will be a set size for inserts if poeple want to create their own mold.

I bought some aluminum stock to make the first mold, this will make up the insert. I have a guy ready to cnc this (much easier to machine so no need for hulk on this occasion)

So any ideas on what to create? Remember this machine is great for creating parts in there hundreds otherwise 3D printing may be the way to go or silicon molding.

HSBNE poker chips or HSBNE tokens.