Hi everybody! I wanted to report some repairs, modifications and upgrades I’ve made on the the big laser.

Repairs

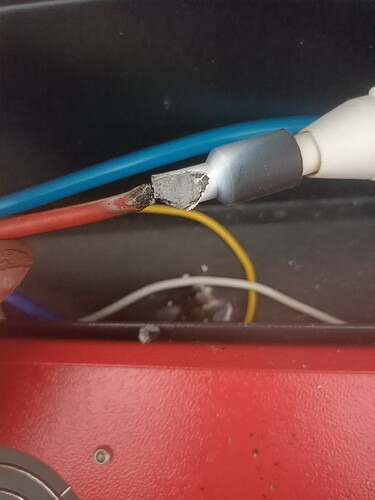

I’ve fit a new high voltage cable on the unit. The old cable was broken near the connector closer to the PSU and it was arching.

Please let me know if the laser is not firing or such.

Modifications and upgrades

Vendor options

I’ve modified the home offset values from 0mm to 10mm. This means that the laser nozzle will always be 10mm padded into the bed of the laser.

I’ve made this to avoid any hard clashes when moving into the home position (I suspect these were making the mirrors to go out of whack).

I’ve modified the homing speed from 200mm/min to 50mm/min. This speed only affects the movements of the laser when is trying to find the home position. Same as above, this was hitting to hard and shaking the whole machine.

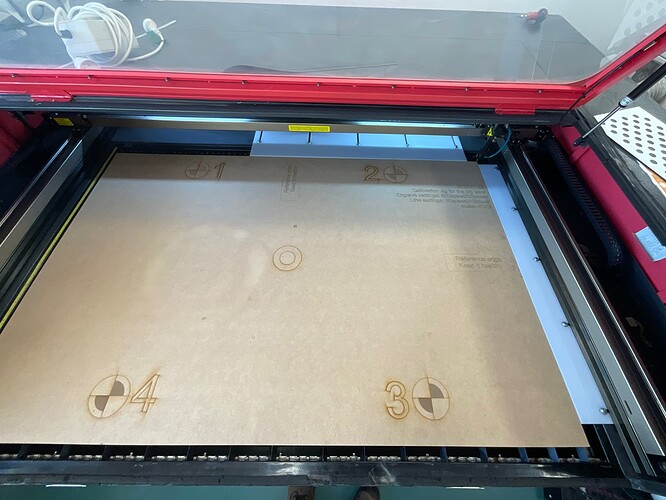

Zero Clearance fence

I’ve machine a couple of M6 holes to allow fixing a permanent fence to allow easy alignment and setup.

The holes are set 200mm apart, so in the future make a new fence should be easy enough.

The current fences, allow to be moved and recut once they get all chewed up.

All recutting of the fences task should be performed by maintainers or people alike. No need for end users to be messing with these.

Now that we have a fence to reference, the alignment of the camera should be way easier, and now the jigs can be used multiple times.

I’ve cut a new jig and indicated in it all the important details.

I’ve realigned the camera and all and it seems to work fine.