CNC Main table arrangement (Bleeder board)

These days I’ve finished setting the main bed/bleeder board.

Tasks that were performed

- Levelled the bed

- Cut the housing for the PVC bushings

- Milled the bushings to spec

Main features of this fixture

-

It permeates the vacuum and its fixed installation avoids having to troubleshoot any leaks

-

Allows to cut a whole 2400x1200 sheet with no hassle

-

The pin arrangement is designed per quadrants, matching the CNC vacuum table, this allows for more efficient use of the vacuum table keeping alignment/repeatability capabilities

-

The locating holes are cut to 22mm which matches with a standard bamboo broom handle from bunnings ($6.99 per broom handle)

-

The bushings are made using 25mm PCV heavy-duty conduit ($3.5 Per length at bunnings)

Ways you could use the table

-

“I just want to screw things and CNC away!” (small-ish pieces, good starting point for beginners)

To do this you simply need to get a piece of melamine (at least 600x600) screw your piece to it and you are ready to go, the vacuum will hold the sacrificial substrate to the table.

To improve this scenario you could:- Flatten the substrate before screwing your piece

- Register your sacrificial substrate using the locating pins

- Screw/pin-nail some fences on your substrate for repetitive operations

- To extend the work area and have a better anchoring to the table, you could mill matching holes on the underside of the substrate so instead of registering against the pins you will insert the pins into your substrate.

-

Making more sophisticated spoil/fixturing boards

You could machine your own jig to fix your workpieces that interlock with the existing pins. Ideas that relate to this is:- MFT style configurations

- Cam clamps

- Using readily available accessories with a MFT style board

We will probably make a couple of this jig so they are readily available

-

Cutting pieces using proper CAM and stock that can be held by just the vacuum

In this case, you simply throw a spoil-board on top of the main bed, skim it and you are off to the races.

How to use the bed, what to do and what not to do

- We want to keep the main bed healthy all the time. This means that you can’t machine it, put screws or nails into it

- You always need to be using some kind of spoil board to make your cuts

- The main bleeder board can’t be moved. Now the bed is fixed using plastic bolts. This way the locating pins stay always on the same spot, allowing the user to fixture their works quickly and with ease

- When the CNC is not in use, the bleeder board should be covered with another board to mitigate the effects of moisture in the environment (this is what makes the board warp and swollen)

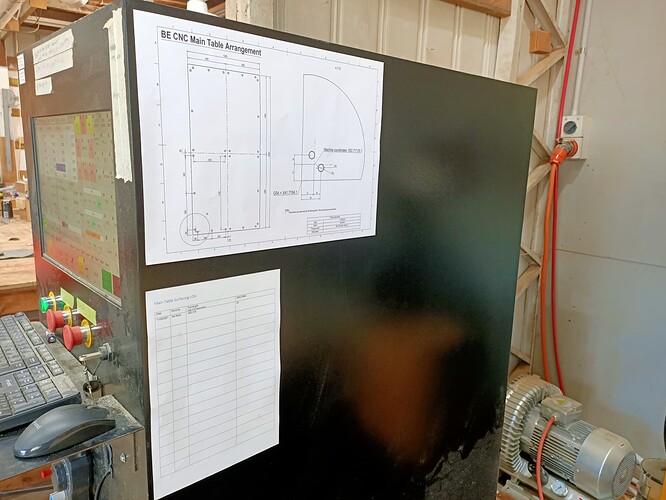

Next to the CNC, you will find a plan, that shows the location of every pin, dimensions of interest and machine coordinate information of points of interest. As well it logs who prepare the bed the last time and when. This information should allow you to set up any work you might want to do.

Here’s a PDF of the drawing

BE CNC Main Table.pdf (144.2 KB)

Surfacing the main bed

Surfacing the main bed is a task that should be performed only when needed or in a reasonable scheduled way.

Surfacing the main bed is a task that should be performed by the CNC supervisors or with at least their involvement and proper authorization.

When the surfacing of the main bed is done we need to log in on the surfacing log next to the CNC. Here we need to put the information of interest so the next person can set up quickly and have an idea of when was the last time surfacing was done.

Here’s a copy of the document

Main Table Surfacing LOG.pdf (79.1 KB)

For the future

I’ve spoken to a couple of cabinet making shops around the space, and they are happy to donate some surplus or cover sheets to us. This will give us the possibility to create jigs and projects.

I would like to get a 32mm MDF/white satin board to make the same fixture but using the whole extend of the bed. The reason we couldn’t do this is because there’s a little bit of a shortage in Australia for MDF boards and Team arrow, who donated the material for the bed, had to get this done now.

In the far future we should look into getting a proper vacuum, like a rotary vane, and not the regenerative type that we have now, this means at least 3 times the pressure we have now. As well these other pumps are less noisy, so troubleshooting leaks is easier.