Hi everyone,

I spent a bit of time this week looking into quality of life in the Digifab printer area, and will be soon writing up a proposal for how we continue to improve ease of use. I’m a huge fan of making things as automated and trouble free as possible.

First up, I did a few simple things in the room that hopefully make it a little more comfortable.

I’ve re-calibrated the right CR-X as it was way out on the Z-zero point. Almost half a mm in fact, which definitely goes to explain why first layers would definitely have had issue going down.

I also went through the room with a rubbish bin and a vacuum, picking up a lot of old filament and dust, as well as putting random things into their correct destinations. We’ll be adding a bin to this room permanently to make it so much easier to deal with the little bits of printer fluff.

I placed the scrapers on cable retractors, to keep them by the printer and also to stop any chance of people dropping them. The cable retractors are soft enough to not present any issue when working with them, and while they are on the right hand side, hopefully any left handed people should be fine with it too. I did spend a bit of time figuring out where to safely place a blade, however if there are issues, let’s fix it

I spent some time looking into the firmware and mainboards of printers we currently have, and unfortunately we can’t quickly add the BLTouch probes to these particular machines as they are, so we’re stuck with old school bed leveling for the time being.

My belief is if we can automate the functions through sensor driven measurement and human friendly display, we’re more likely to be able to detect when a printer needs a manual intervention, and also enable the non-printer-nerds to self repair many common issues. I’ll happily buy anyone a can of soft drink if they’re prepared to listen to my rant about the use of paper and perceived friction to calibrate what is a CNC machine

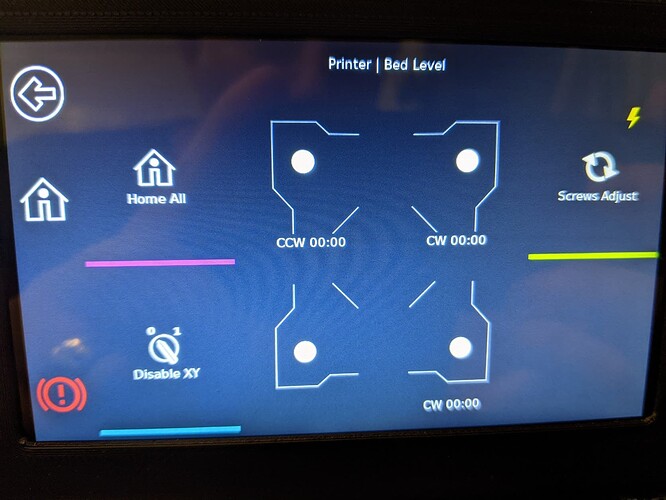

For an example of my thoughts on this, is this an Ender 3 that was given to me, and the bed screw leveling process with my workflow. What’s showing on the touch screen is the measured bed screw points, and exactly how many hours, minutes and what direction I need to turn the bed screws to level it. As measured by a bed probe, the four bed screws on that machine are within 0.016mm (i.e. less than 1 minute of turn on a M4 coarse thread). This took me approximately a minute to completely level to this accuracy, and I’d place good money on the v-wheels inducing more error than I need to adjust at this point.