Hokay, heres what needs to be done with the dust collection.

Extraction Unit Home

Theres a concrete bunker around the back where the compressor lives. We need to rebuild around that to make a shed that can fit both comfortably. I’ve estimated about 60m of standard framing pine, bunnies is the cheapest price there. For walls we have a heap of roofing offcuts around the place we can screw on there in a tile style to weather protect it all.

Essentially need to buy the timber and get going. I’ve already bought a heap of appropriate screws and masonry anchors etc.

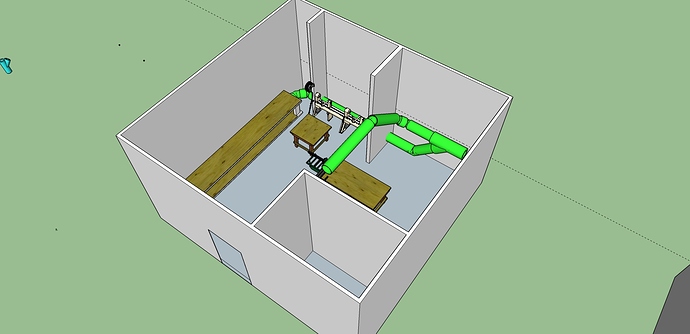

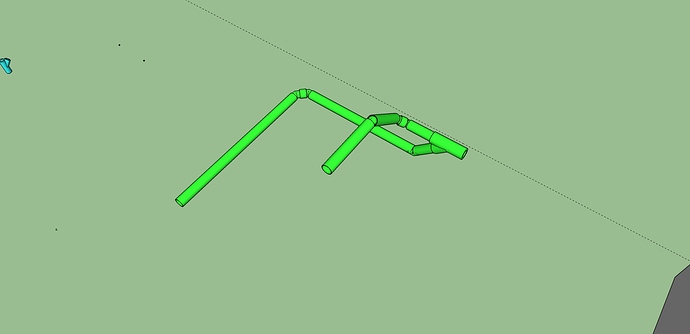

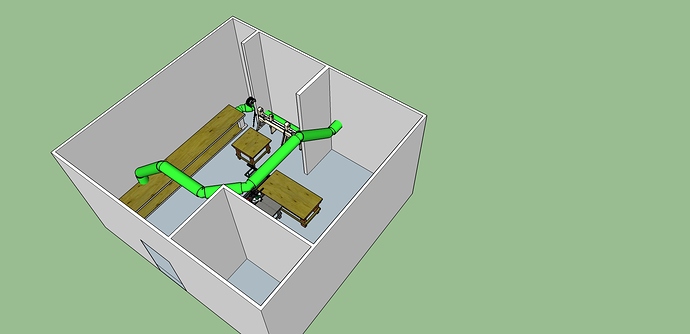

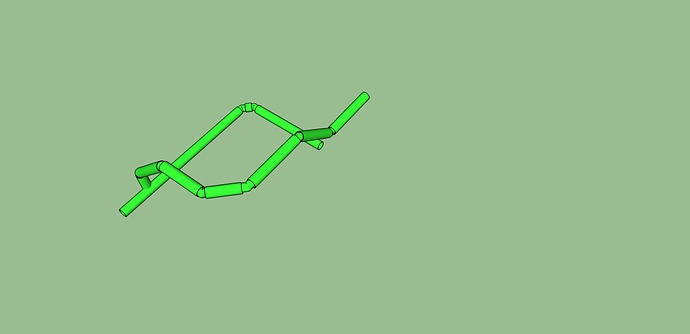

Ducting

As for the ducting, I’d like to pipe in a main bus thats 8", and we can reduce that down to 6" for drops to tools. Theres some argument for going straight to 4" but the cost difference is negligable and keeping the bus as wide as possible for as long as possible is ideal.

Blast gate placement will be as close to the main bus as possible as thats optimal for reducing the area to pull a vacuum on.

You can check the Woodwork 2017 thread for an initial concept about bus layout.

Materials wise I’m looking to utilise DWV PVC pipe, do all bends with 45º elbow pairs to reduce corner radius. Join everything with aluminium plumbers tape, which will seal well but not lock us in like pvc cement would.

Air Filtering

I think we may have two gated ports on the main bus in the middle of the room to open for air filtering purposes.

Down draft table

Might be part of the outfeed table or another piece of furniture, but a down draft table for sanding would be very nice to have.

Sweep Ports?

We may drop a few lines to the ground with a shroud so you can sweep directly into the system, make cleanup super easy.

Blast Gate Automation

This is the parts list to actuate a gate. Gates are about $12-20 depending on material, size etc. Aluminium gates might be worth it just for durability. 100mm piston is 4", 150mm for 6", 200mm for 8". We’d need a few minor one off parts, like a regulator for the air system.

- new air L type 6mm M5 threaded elbow connector 90 degree PL 6 M5 pu hose nylon pipe pneumatic fitting-in Pneumatic Parts from Home Improvement on Aliexpress.com | Alibaba Group

- 90 deg 1/4 thread Pneumatic fittings L6 02 fitting 6MM tube quick connector-in Pneumatic Parts from Home Improvement on Aliexpress.com | Alibaba Group

- 4A210 08 Pneumatic Solenoid Valve 12V 5 Ports 2 Positions Solenoid Valve Control,Reversing,Air Valve-in Valves from Home Improvement on Aliexpress.com | Alibaba Group

- New 10Pcs/Lot Sinter Bronze Pneumatic Muffler Silencer Air Flow Speed Control 1/8 Valve-in Pneumatic Parts from Home Improvement on Aliexpress.com | Alibaba Group

- 1 Pcs 10mm Bore 100mm Stroke CDJ2B Mini Pneumatic Air Cylinder-in Pneumatic Parts from Home Improvement on Aliexpress.com | Alibaba Group

- CDJ2B10 100 SMC Type CDJ2B series Mini Air Cylinder CDJ2B10*100 10mm Bore 100mm Stroke Pneumatic Cylinder 10X100-in Pneumatic Parts from Home Improvement on Aliexpress.com | Alibaba Group

- Air Application Tube

Automation Electronics

We will need to detect tool on and actuate the right blast gate open. I think perhaps this may be best done with a central controller of some kind because of a few factors:

- There needs to be simple timeouts to extract post machine shutoff

- The motor shouldnt be cycled on/off constantly, once every 10-15min, so some smarts about staying on or not etc.

- We need 3 gates open min at any time, the machine is powerful and any less will stress it out with not enough air flow. So a smart controller can try and pop air filtering general ports to meet that minimum number.

None of this is scary stuff to figure out. Might decide to go with 24v control just for voltage drop management over runs.

We should be able to detect ‘tool on’ with the simple current detectors that you can buy on ebay. I dont want to piggyback or interface with any interlock stuff because I want the system to stand on its own.

May need some manual switching as well, just for things like hand power tools, or force the system on for air cleaning, or sweep ports.

Fin

I think thats about it? Thoughts? Concerns? Offers to help? Much appreciated.