Hand tools revamping

Introduction

I’ve been thinking for some time about renewing the hand tools set and the way we manage them in the woodshop.

I want to setup the guidelines and the range of the handtools that you can find on the shop. This will allow members to have a better experience when they work on shop, they will know what to expect and they will not lose time looking for tools that we don’t have. As well, having a standardized set of tools, allows for better tracking, documentation and availability. This will open the door for professionals and alike to be keen on running workshops and classes on the shop.

Right now, we have an assortment of tools that have come from different places, they’re being stored on the tool wall and they tend to float around the space. My plan is to eventually replace all this tools, we might keep some stuff though.

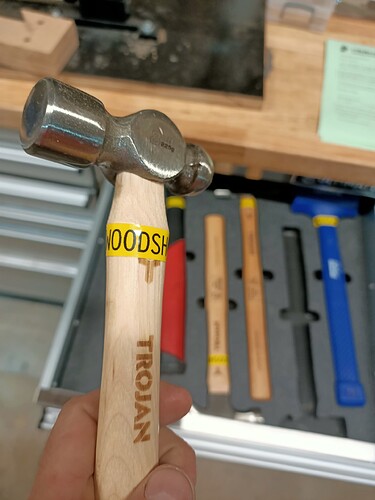

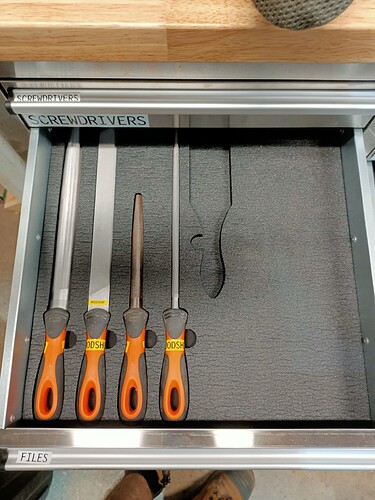

To improve this, I want to start buying new tools, some of them more than one of the same. The kind of tools that I want to get, is the kind that can get the job done but don’t cost millions. They will be stored on a tool chest, using foam inserts.

For the ones of you who don’t know, I’ve designed a system that allow us to do this in a fast, streamlined fashion. So, implementing new tools following this new standard shouldn’t be a hassle.

The standard for tools will be:

- Every tool has a home (foam insert)

- Tools are labelled using “GPS tape”. This is simply putting a piece of colour tape on the tool, so if the tool leaves the shop, we could track it.

- Every tool is in the wiki with a picture, brief description and its location on the tool box.

Storage

To store the tools, I want to use a tool chest with drawers. This method of storing, has good dust control and it goes well with foam.

This is the one I want to get, I’ve check it and it’s good quality and it will match nicely with the fitout of our shop.

https://www.bunnings.com.au/ultimate-storage-72-15-drawer-tool-trolley_p6120457

The range

Like I said, I want to stick to the basics. I want to have a set of tools that will allow us to make basic joinery and cabinetry. As well I want to have some tools available for members projects but more oriented to machine fitting, like wrenches, keys and sockets.

Main categories will be:

- Chisels

- Saws

- Sharpening

- Marking and measuring

- Hammers and mallets

- Reworking tools (spanners, keys, sockets, clippers, screwdrivers)

- Drill bits and driver bits

Here’s a list of what I have in mind.

How to do it

To start doing this we will need to get the storage first, and from there we will start buying tools in stages and clearing the tools from the walls and revamping the hand tools area. This will allow us to distribute the work load with other team matters and as well test the system/idea.

This will be happening at the same time we change the layout of the shop and revamp some of the shop fitouts.

What to do with the old tools

The tools we chose not to keep could be use by others teams, could be taken by members or could be donated to friendly associations.