Foam cutter is in revision 2.5

Purpose:

To cut 25mm blue modelmaking foam, sourced from AusBuild, to be used as terrain for the tabletop wargame Battletech.

Foam will be cut into multi-hexagonal shaped ‘hills’ 1.5" edge to edge, smooth cuts are desired as foam will be painted and flocked.

Build:

1.0 Initially the Foam cutter was built with laminated mdf, aluminium strip, nichrome wire, switch, a few 1ohm 10W resistors. It was wonky, didnt cut straight and was probably going to cause a fire.

Revision 2 increased the base cutting table size to larger than A3, lowered the cutting arm to reduce wire bending, changed to an 8V 1A plugpack and increased resistor load to 4.4ohms.

This was successful at cutting wattage but burned out the plugpack because I didnt math.

Revision 2.5

My lack of electrical maths knowledge was corrected by some fellow hackers and a laptop power supply was utilised, providing 24V 1.7A. With some bigger fatter resistors providing 16 ohms the cutter was optimised. However the 25Watt main resistor created amazing amounts of excess heat and was a concern for the wood frame.

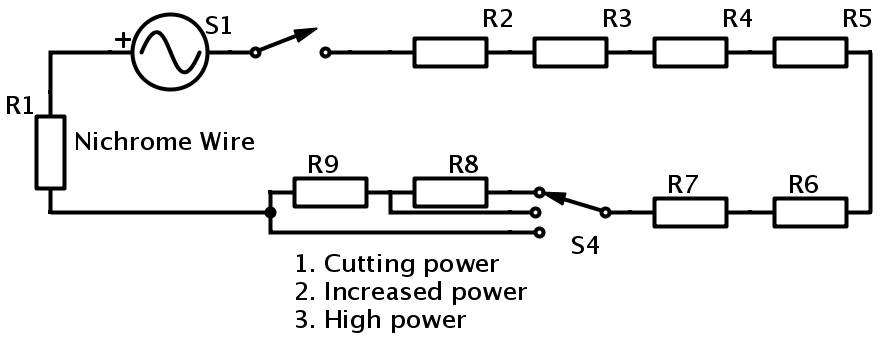

The maths was worked out and a system of using a three way switch to control the temperature so that Revision 3.0 will have a 12V 3A power supply, greatly reduced heat generation, and switchable temperature control.

Rev 2.0

Schema for Rev 3.0

Planned: 4.0 might incorporate PWM and an elevated cutting head with auto-tensioner.