I took this pic of the laser PSU last week… will it do?

https://docs.google.com/file/d/0BwRnTkIcZzCoSXZ2SUFPNFVmbWc/edit

I think you will find postage to and from isn’t included as part of the warranty return under the ACCC.

It’s something you need to pay for when shopping online.

So… New PSU has arrived YAY…

Though the build quality is questionable on the replacement thus I’m asking everyone

DO NOT PLACE YOUR FINGERS NEAR THIS UNIT … Please…

If anyone has some sticky rubber to place on the edge of the case to stop the HV line chafing even more on the case that would be grand!

Will see how well this works, then I will contact the people…

I’ll try to grab some instant gasket on my way in. Failing that maybe grab

the grommet from one of the old power supplies in the bone yard?

So does that mean the psu has been installed? If not… where is it?..

The new psu has been installed thanks @lhovo for making that happen, laser cutter from my understanding is ready for use.

Laser cutter power is flaky, even after cleaning and aligning the optiics. I couldn’t even get it to consistantly cut clean through 3mm acrylic, even at 90% power/2mm a second.

The power is inconsistant across the entire bed. At this point, it’s either one of three things:

- Power supply.

2 Tube. - Coolant in the tube - if it has antifreeze in it (most automotive coolant does) then it can actually prevent the high voltage to the tube transmitting properly and eventually kills the tube.

Also I’m referencing - http://www.rabbitlaserusa.com/FAQ/FAQ_28/FAQ_28.html

Rabbit laser USA resell redsails and similar from china and do much of their support for them in the US.

They have an extensive FAQ here - http://www.rabbitlaserusa.com/FAQ/index.html

I believe the bulk of the issues arise from alignment. If the alignment isnt EXACTLY perfect, it just wont cut. The alignment changes with position which explains the inconsistency across the bed. I feel the addition of an in line visible laser so we can align it more accurately, faster and without having to sit there pulsing pieces of paper. I don’t have a great deal of faith in that power supply either, but I think the bulk of the issue arises from alignment.

I just verified the alignment, it’s pretty spot-on – and yet, still has really flaky cutting power. I Blu-Tac’ed a piece of acrylic on a slant to try and work out the optimal focal distance, and got two wildly different results; one which cut best at 12mm, and another which cut uniformly badly, which suggests to me that it is indeed the power supply.

As for the coolant, the green stuff in there is not rated as antifreeze - it is a “Type B” coolant which only needs to display corrosion-inhibitor properties. It could still contain a small proportion of glycol (up to maybe 3% – some concentrates mix down to 1.8%), however the only information I’ve been able to find on this has been scattered across forum posts on the greater Interwebs. By contrast, antifreeze (Type A coolant) is supposedly red in colour and contains upwards of 33% glycol.

If the small quantity of glycol in the radiator fluid were causing problems, what alternatives would we have for coolant? It would need at a minimum an anti-fouling agent, and to not deposit scale inside the machine.

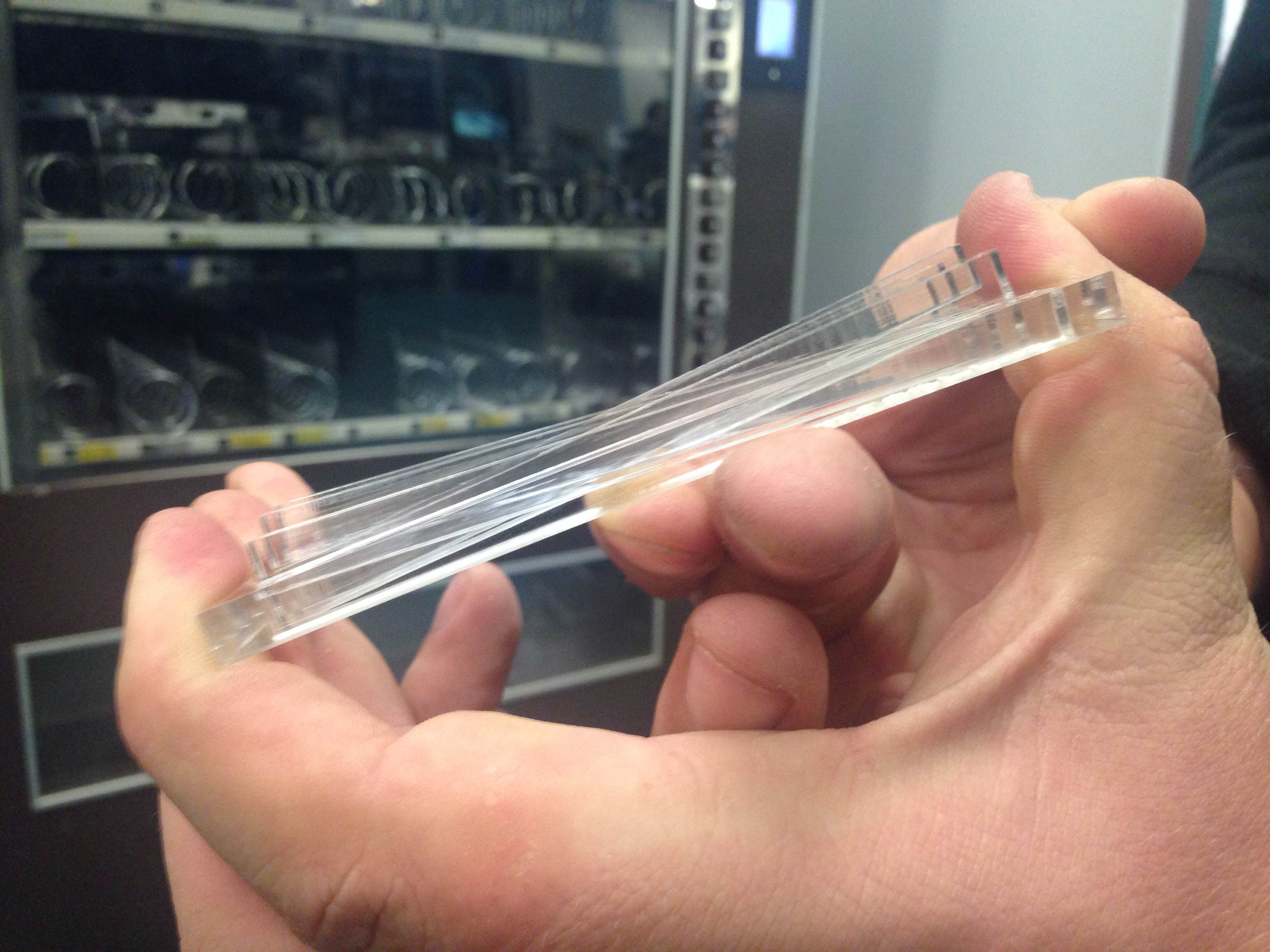

So I cut a 2-metre groove in a piece of scrap acrylic the other day. Here’s what the power output looks like.

great news everyone the laser cutting is running a hell of a lot better then it was before after a good clean and realignment,

it is now cutting through the test @LuminousElement made up for us pic below, i was able to spread apart the acrylic with little to no effort

Big thanks goto @lhovo and @merseyless for helping me clean and align the laser again.

I guess the next question is: Will it consistently run a job longer

than 30 or 60 minutes…? that was the issue before… after a while

the thing starts to appear to “loose power” and whatnot, till it

eventually can’t barely cut anything at all…?

I firmly believe it was a alignment issue and the “loss” of power was due to the positioning of the mirrors plus grit.

But only time will tell.

@merseyless has offered to help code the access system to get RFID working, and for that I say a HUGE thank you.

That’s not the issue I’ve been having since the power was replaced buzz.

Someone keeps leaving big fat fingerprints on the final mirror which explains the cutting inconstancy that I’ve been getting.

Plus the support bars inside are literally caked in gunk right now which aerosolizes whenever someone cuts over them and some of that ends up on the mirrors.

For future use I’d like to require users of it to wipe down the support bars before moving on.

Also note that the focusing distance is actually 12mm with the weaker 50w supply. I’m sourcing parts to build a touch probe stepper driven attachment to adjust this automatically for you.

Then you’ll be firmly disappointed to look through the old photos. If the loss of power were due to alignment there would be a recognisable pattern to the “dim” patches on the cut piece. Also, the 1-metre gauge (which is what @crofty cut in that last picture) wasn’t long enough to reproduce the issue. I did a brief test after everything was apparently fixed on Tuesday, holding the pulse button while scrolling at 2mm @ 90% – and this didn’t cut through 6mm acrylic.

I’ll try again with the 2-metre track to diagnose it.

On Tuesday night we were cutting at 3mm @ 90% and it was cutting through

Fire suppressant has been installed!!

Laser cutting was working, now it fuck.

Opto-something on the X endstop is broken. Simeon is apparently replacing it.