After being asked several times to get some opto’s I have followed through and have them in my hands.

Will bring them tonight.

Is the new smoothieboard still on the way? Am waiting on it to arrive for us to hook it all up.

Smoothieboard has arrived, @crofty and I will likely be in this weekend installing it.

Just FYI to set expectations, the smoothieboard can’t do straight raster engraving currently (image to engraving pattern). All your lines, shapes and engraving will need to be done in a vector program like Inkscape or Illustrator or any CAD software.

I’m a little concerned about the wisdom of fitting a completely new controller board to the laser cutter. I imagine it will take quite a bit of rewiring which could make reinstalling the original DSP a real pain. Is there a reason the DSP controller has not been sent back to the supplier yet?

Any modification needs to be done is such a way that it can be restored to its original condition easily.

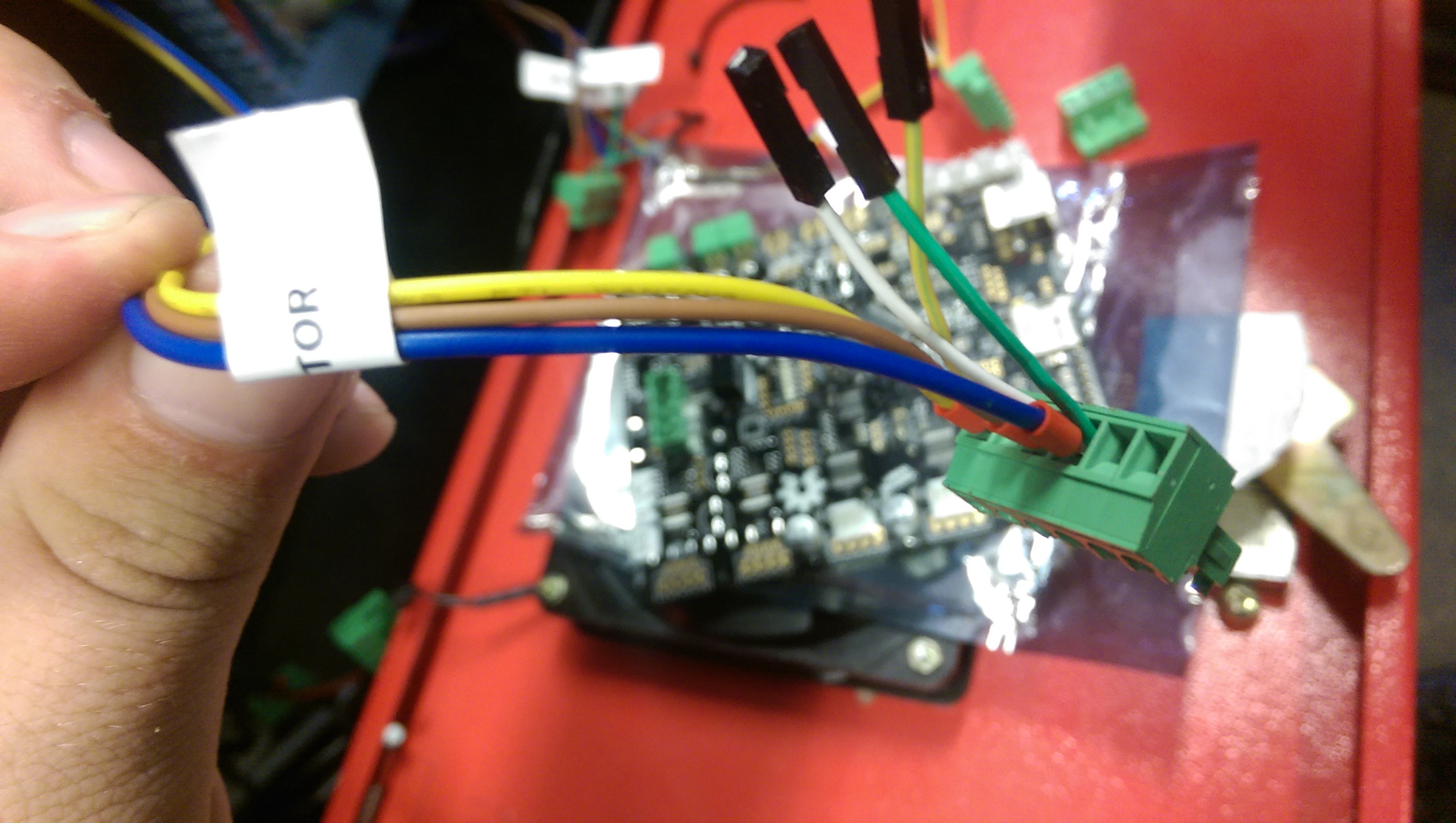

Just to expand on the post by @crofty we are piggybacking on the existing 6-pin terminal headers that the DSP board used and we have labelled all of the cables and their individual wires with their purpose.

We are now creating new wiring harnesses for the stepper drivers because they were wired in a nonsensical way.

Pre-tidying of the cables, but it’s alive

Now for dinner and then configurationing.

Another update, the X and Y steps per mm are tuned in and correct.

Homing is working, so clearly all the endstop faults were on the previous DSP board.

PWM control of the laser evaded us last night, but it turns out we were using the wrong pinout on the smoothieboard and expecting pwm on that. We’ll fix that on Tuesday and then we should be good to go aside from workflow.

Hey Nog, unfortunately i wont be able to help on Tuesday night as I’m busy that night now. Good luck though!

Laser now fires via PWM from the Smoothieboard

We’ve also implemented the interlock on the door again so the laser stops firing when you lift the door.

@Leon what’s your workflow like?

Nice work guys! What was the final wiring you ended up with for the PWM? What was causing the grief the other day, was it the smoothie pinout?

I’m using inkscape at the moment. My bed is 300x200 so I’ve created a template in inkscape which I’ve attached. Keep in mind that the origin is the bottom left, so essentially you need to flip it before converting it.

For some sample gcode and my inkscape template you can find them here :

You can change the size of your template in mm by pressing ctrl+shift+d (Set the units to pixels) then saving the template somewhere safe. Place your designs in the bottom left which equates to the top left of the laser bed.

The laser cuts fine and reliably in the right hand side of the bed (12mm

from the job)

As such I do think its a alignment problem.

Do you want some demin water currently I have 30345L in tank. I will drop

some in on Tue for you. If you want me to drop some in tomorrow let me know.

Hmmmm, this is totally, totally coincidental in my brain, but all these

issues seem to have started with the coolant addition, no?

I speak from not having done any research, but distilled water is the

recommended thing isnt it?

A bit distressing this machine is having so many issues.

Holy necro-posts batman.

Firstly I agree with @nogthree necro post.

Secondly we would ideally have a biocide in the coolant, I’ve recommended we buy a bottle of PC nuke or similar antimicrobial agent and add a few drops to distilled water in the past, but water alone is what is currently installed. Interestedly enough the coolant that was installed did not have such an agent, only anti-corrosion, which we don’t really need as the lazer cutter side of the loop is entirely glass, so the pump should not have anything in the loop that would have a galvanic potential with its iron based construction.