So, last weekend we had the Yarraman to Wulkuraka bike ride.

https://www.brisbanewicen.org.au/2018/08/04/y2w/

(Yes, HSBNE gets a mention. You guys helped make the ride happen.)

All in all, things went okay, but one problem that was highlighted was the mount for the front basket. The basket is designed for a road bike, and so its mount can only accommodate handlebars that are about 20mm in diameter. Unfortunately those for a mountain bike are bigger, about 30mm in diameter.

My solution to this in 2012 was to use a length of former broomstick handle. Cut a length off, mount the basket mount to that, then hose-clamp it to the handlebars. Those two hose clamps worked well on city roads. The screw was added some time later to help stabilise things, but I never got around to replicating it on the other side. It didn’t seem to slip off on Brisbane roads.

However, on the rough and tumble of the Brisbane Valley Rail Trail, that left-hand one kept trying to slide down to the thinner part of the handlebars and so the whole basket would then start swinging from the right-hand clamp, the screw being the only thing preventing the basket from falling to the ground.

Now, while I could put another screw in for the left-hand side, it’s worth observing the splitting of the wood observable from the right-side, and also this bit of wood is very heavily compressed on the left side as well. Basically, it’s knackered, and so it’s time for a replacement.

I could replace it with a longer piece of metal tube, that is what I did on my other bike (because the piece of broomstick handle there split through completely!), but really these are kludges around the real issue: the mount is not designed to fit to a mountain bike.

My thinking is this: the mount is in four parts.

Part 1 is the part the basket actually fits to:

There is absolutely nothing wrong with this part, so my thinking is whatever I make, I just design it with the view that it mates with the sockets on each side of this part. The critical detail is that “ratcheted” surface which prevents slippage.

Parts 2 and 3 are what mate with this surface and provide one half of the clamp for the handlebars:

Nothing wrong with these parts other than the fact that the section that clamps the handlebars has a too small a diameter.

Part 4 is the other half of that clamp… and yes, it had a hairline fracture that became not-so-hairline after disassembly:

My thinking is this:

- model replacement parts 2, 3 and 4 to suit a mountain bike.

- either:

2.1. convert the models into a design for moulds for 3D printing OR

2.2. 3D print the parts and make a mould from them - use the created moulds to make the real parts (possibly using some hardened resin)

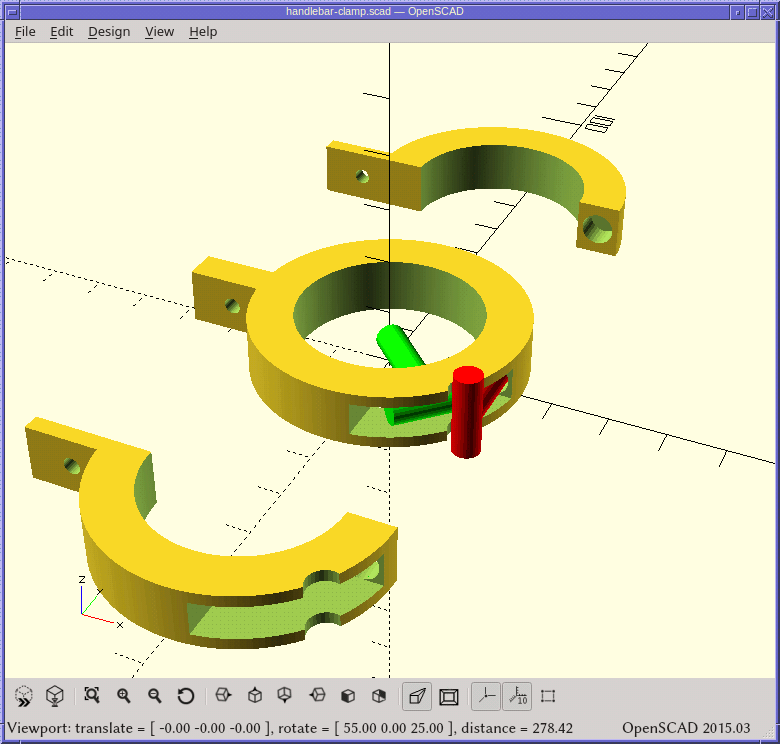

I’m open to other ideas, but that’s the thought at this moment. I’ll obviously need to get some dimensions going then break out OpenSCAD to create the design.