Brakes Upgrade

So another thing I’ve been working on to improve safety and maintainability of my scoot is to replace the existing calipers with a hydraulic cable-actuated caliper set from xtech. This has a few benefits, mostly around clamping power and better proportional control/non floating center but specifically it uses a common brake pad style that is super easy to source in any bike shop in AU. The existing m365 brake pads aren’t easy to source here and typically require ordering from china.

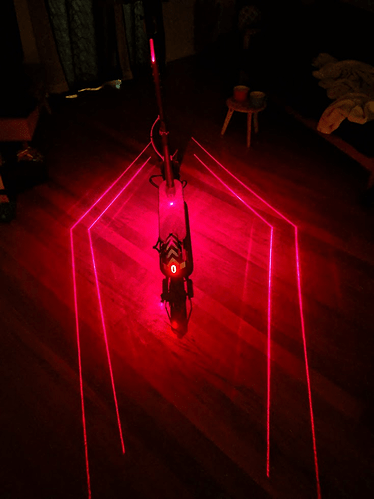

It looks like this:

I’d seen a bunch of spanish/brazilian youtubers using these on their m365 but there wasn’t much english documentation. The best I’d found so far was this video by Tommy Lepo - https://www.youtube.com/watch?v=xs4zpBWHW1Y

Now the existing mount holes on the m365 are significantly different to those, being 50mm apart and these calipers being 73mm apart. Additionally, the curve on the bottom half of the caliper doesn’t match up with those mounting holes.

This leads to some hacky but successful stuff like in Tommy’s video where he makes a bracket out of 3mm alu with this hole spacing:

Hole pattern

Installed bracket

This looked a bit janky to me and I didn’t want to stack washers and hope for the best. So I hung around a bunch in some non-english-speaking groups dedicated to m365 modding and saw a bunch of custom brackets being sold only in Brazil. I also found 3d printed versions which seemed like an even worse idea… so I asked if anyone could link me to that bracket or sell it to me.

A helpful person pointed me at this bracket, with PM-PM-F/R203 stamped on it.

I dutifully bought this, the calipers and a larger brake rotor which was recommended by a video on JR-Gadget’s channel - https://www.youtube.com/watch?v=XadDCJK8udU

It all arrived and I excitedly pulled off the old calipers and went to mount it all. Slight problem, the hole pattern on the bracket was still wrong. It matched the new calipers, but not the old mounting holes. Additionally the bracket was so tall that the brake caliper body was rubbing against the inside of my rear hub.

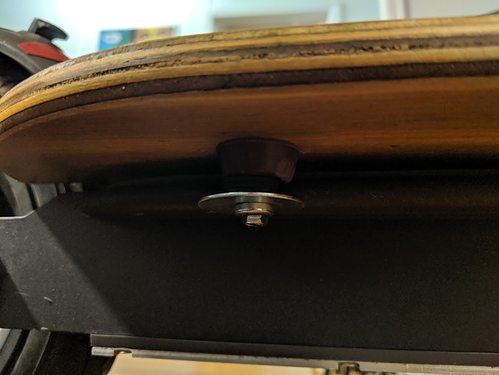

Dejected, I dug around and found this video by Alexander Kompmaister - https://www.youtube.com/watch?v=U7Q9N7KM8gE and discovered I would need to shave the mounting points down to 10mm and drill the new hole. The video didn’t go into how the second original mounting lug was done and as you can see there’s no clearance under the calipers to fit a full head bolt so I decided I’d use some m5 grub screws.

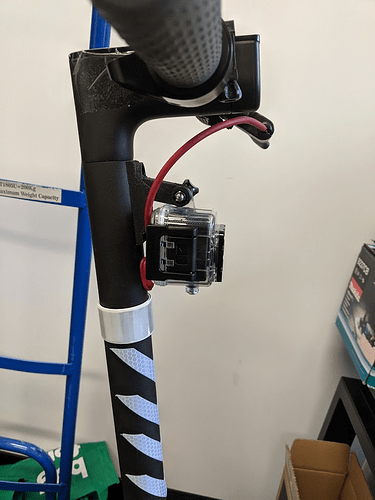

Fully Mounted:

Bracket Modifications required:

New Drill hole (23mm, based on Tommy’s diagram above):

Over the past fortnight whilst I’ve had time I cut off the extra height of the mounting lugs, cleaned that up and then using a belt sander carved out the extra clearance required to put the calipers up against the mount.

Last night I finally got around to drilling the second hole on the mill, using an m6 tap to index the initial hole in the mill and then pulling the tap out, moving the mill 23mm across and drilling the new hole and then tapping it.

Of course, I happened to brainfart and drilled and tapped it for m6 instead of m5. This is fine, but it does mean I now need to nip out for some m6 grub screws and drill out the original mounting hole to m6 as well.

Hopefully the next update will be with the new calipers on as shown in Alexander’s videos above.