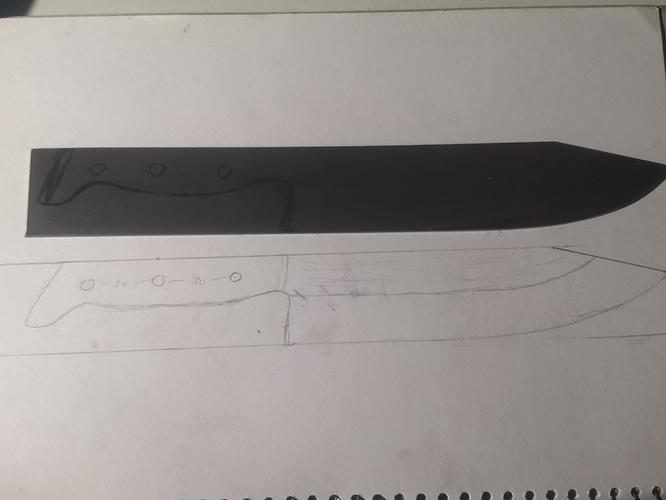

I need to get myself some kitchen knifes so I figured I’d make some myself. The material I have chosen to make them out of is RWL34 Damascus stainless steel from Artisan’s Online after I found it is one of the most recommended stainless steels in the knife making community. While it is labelled as a Damascus, it doesn’t have the cool patterns that most commercial Damascus knives do as it is actually a pressed powder which allows for a very fine grain. I plan on making the scales from Tasmanian oak and attach them to the handle with epoxy and Corby screws.

The process I have to make the knife is as follows:

- Draw design for knife

- Drill holes in handle

- Cut out the profile of the knife and bring to size with files or a linisher

- Grind main bevels

- Wrap knife in heat treat foil

- Harden knife at 1080C for 50min inside foil

- Clamp knife in aluminium to achieve a clamp quench

- Deep freeze knife for 2h in dry ice + metho to complete austenitizing of steel

- Temper for 2h at 200C for a final hardness of ~60HRC. This hardness is a good compromise for a relatively thin knife.

- Clean oxidisation off knife

- Bring all faces to a 240grit finish (polished knifes are not great for kitchen use as things stick to them)

- Sand 20deg cutting edge on belt sander

- Cut stock for scales into oversized rectangles

- Drill holes in scales

- Cut oversized profile of scales

- Epoxy scales to knife and install Corby fasteners

- After epoxy is cured, sand scales to final shape

- Oil scales

- Sharpen bevel using scary sharp method up to 4000 grit

So far, I have started shaping the stock with a hacksaw and files but need to drill the handle holes before continuing further as it will be difficult to clamp in a vice after being cut to final shape. I have attached a picture below of my sketched design and cutting progress so far.