Part of the storage solution we have been working towards for some time now has been sheet good storage. Sheets of plywood, acrylic, sheet metal, whatever. Big flat things.

Long storage (Done!!)- Sheet Goods Storage ← this bad boy

- Misc ← the members storage and boneyard containers.

I’ve been talking with a few people about what to do for sheet goods, trying to figure out a solution. The other night, @Ryan2 and I hashed out a buuunch of ideas. This post is just to communicate our thinking and invite positive discussion and contribution.

TLDR

The best option for sheet storage seems to be 4C, as its comparable cost to anything we could build, if not cheaper, and we can just buy it and use it, no build required. It will give us more space in containers for shelving/pallet racking, so it seems like a win overall.

The ideas/options:

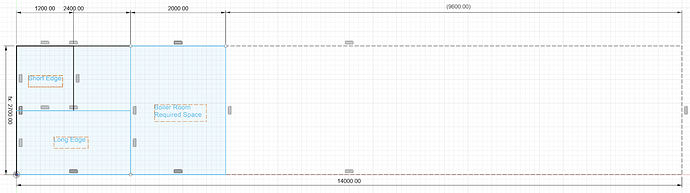

1 Installing racks in the members storage and boneyard containers.

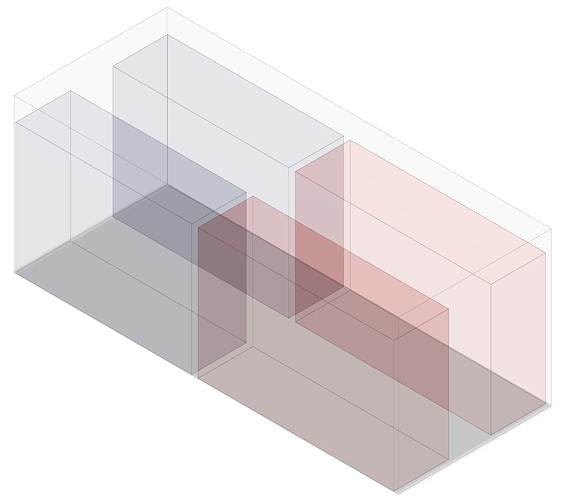

The idea would be to have pallet racks/shelves at the back (blue), and special sheet storage systems at the front (red). Would leave about 700mm corridor in the middle.

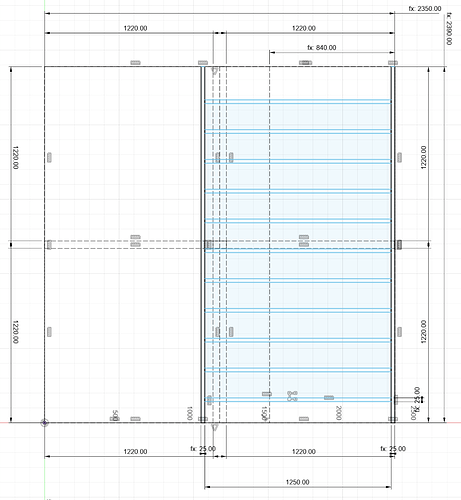

1A Two level vertical storage

This was the first idea, just a basic 2 level comb, sheets stored on edge. Problem is that the top level doesnt have enough space for a standard sheet. We had other versions of this that had smaller piece storage, but just for comparison sake keeping this simple atm. Since the top shelf wouldnt store a full sheet, cant really count it.

Gives 840mm x2 per container, 2 containers, 3.4m storage

1B Two level vertical storage if it worked

Gives 840mm x4 per container, 2 containers, 6.8m storage

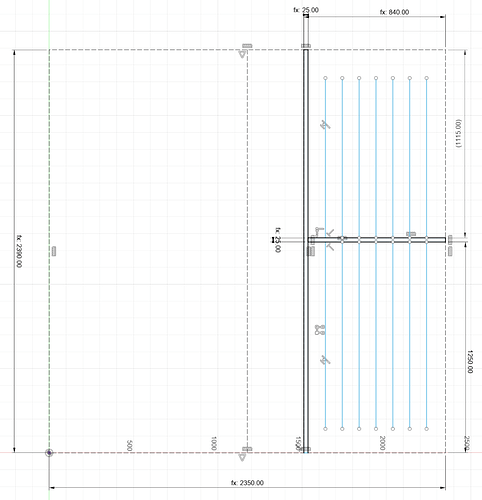

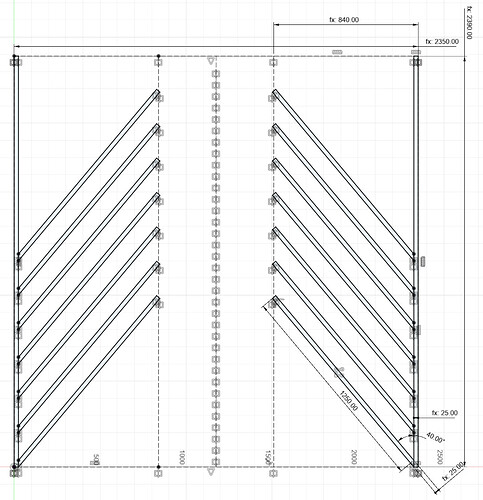

1C Angled storage

Ok so the two level doesnt work great, what about angled storage. Kind of a pain to build and make strong but possible. Makes for weird space usage.

200mm * 7 * 2 per container, 2 containers, 5.6m storage

I did some napkin math on cost to build this, in 25mm shs,

7*1250+2400=11150. * 6 = 66900, * 4 = 267600. So approx 268m

$5.75/m for 2mm from early bird. = $1541

1D Stored Flat

Cant fit 2 sets, makes the access to the back awkward/weird.

Nominally ~2400mm, x1 per container, 2 containers, 4.8m storage

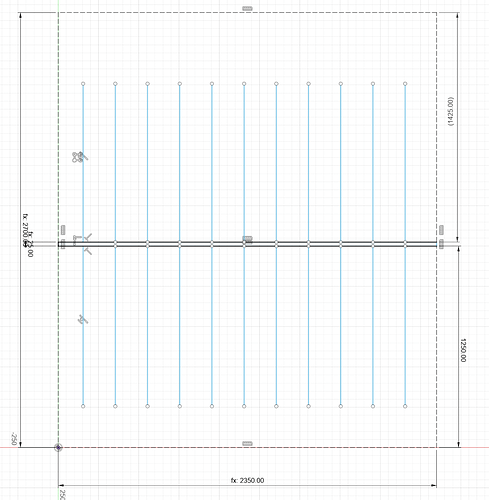

2 Installing racks in the 40ft HC container.

Because its HC (High Cube) the internal height is 2.7m, or 2.58 at the door.

2A Dual level storage at the doors, on long edge

This would push the boilerroom back by ~2.4m, eat 2.4m of that container that would otherwise be workspace.

Nominal 2400*2, gives 4.8m storage

2B Sheet storage on short end

Literally just putting them up on short end, which you cant do in normal container cos of the height. the build would be the simples, just a set of bars as a comb. Would take 1.2m of the container instead of 2.4.

Gives 2.4m storage

3 Buy a side opening 20ft container

Because its side opening its a much easier use of the space. They seem to be going on the market at the moment for $3.6k. All the issues about building shelving and where to put it and landlord etc obv remain. Its not a serious suggestion, just listing options. You can buy HC versions but i assume they are super expensive.

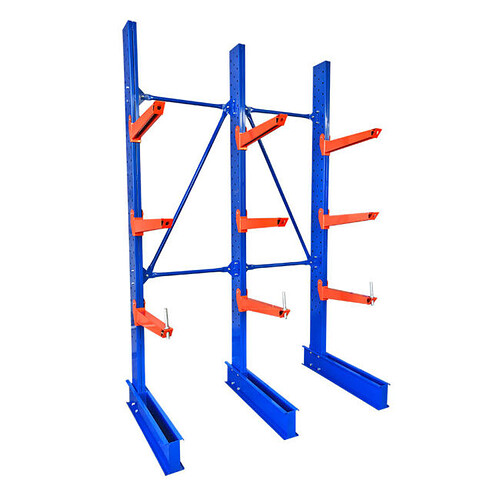

4 Cantilevered racking

This is the industry standard way of storing stuff. I found this place online:

Price of a rack seems to be sort of $1k to $3.5k.

It would also be better for ‘weird sizes’, ie anything not 2.4x1.2m.

We can denote different areas of the racks for different purposes. And it might make sense to store items on edge rather than flat, depending. details details.

The question is where would it live.

4A Just chuck it in metalshop

Really, really, really dont want to do this. The shops should be for working area only.

4B Build it a house

We could put it up against a wall, say woodshop, and give it a roof and sides and some sort of front. Sounds like a pain to be honest, again landlord issues etc.

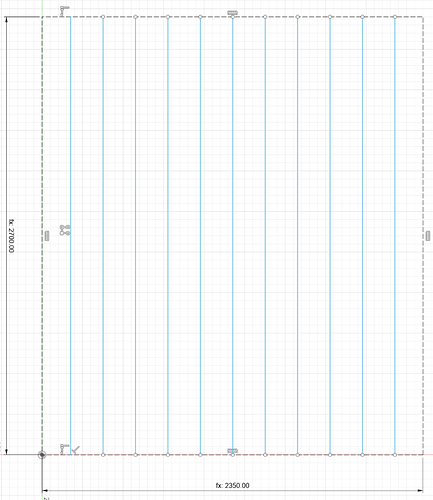

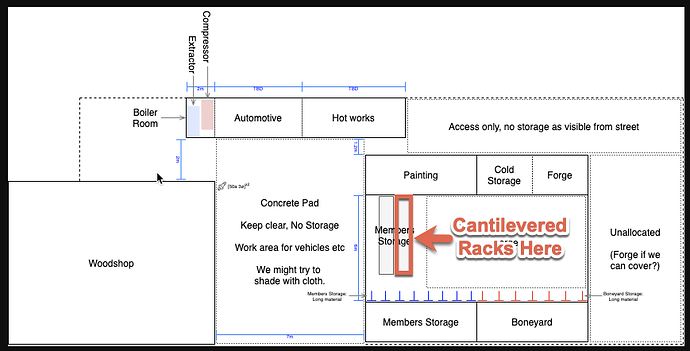

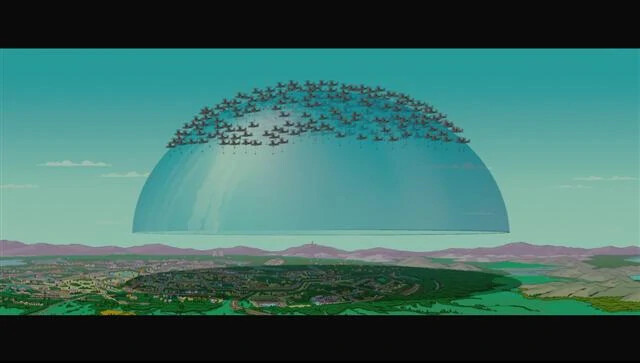

4C UNDER THE DOME

no seriously.

The idea being we swap what was going to be some pallet racking into cantilevered racking. Materials would be reasonably protected by the dome, at most we would need a tarp on the back of the racking. The biggest risk is basically just dust from forge.

You can get them in various heights, widths. the containers are 6m apart, so 2 sets of racks could fit, giving 2.4m*2 by say 3m of height, so 14.4m storage.