This is a brief how too

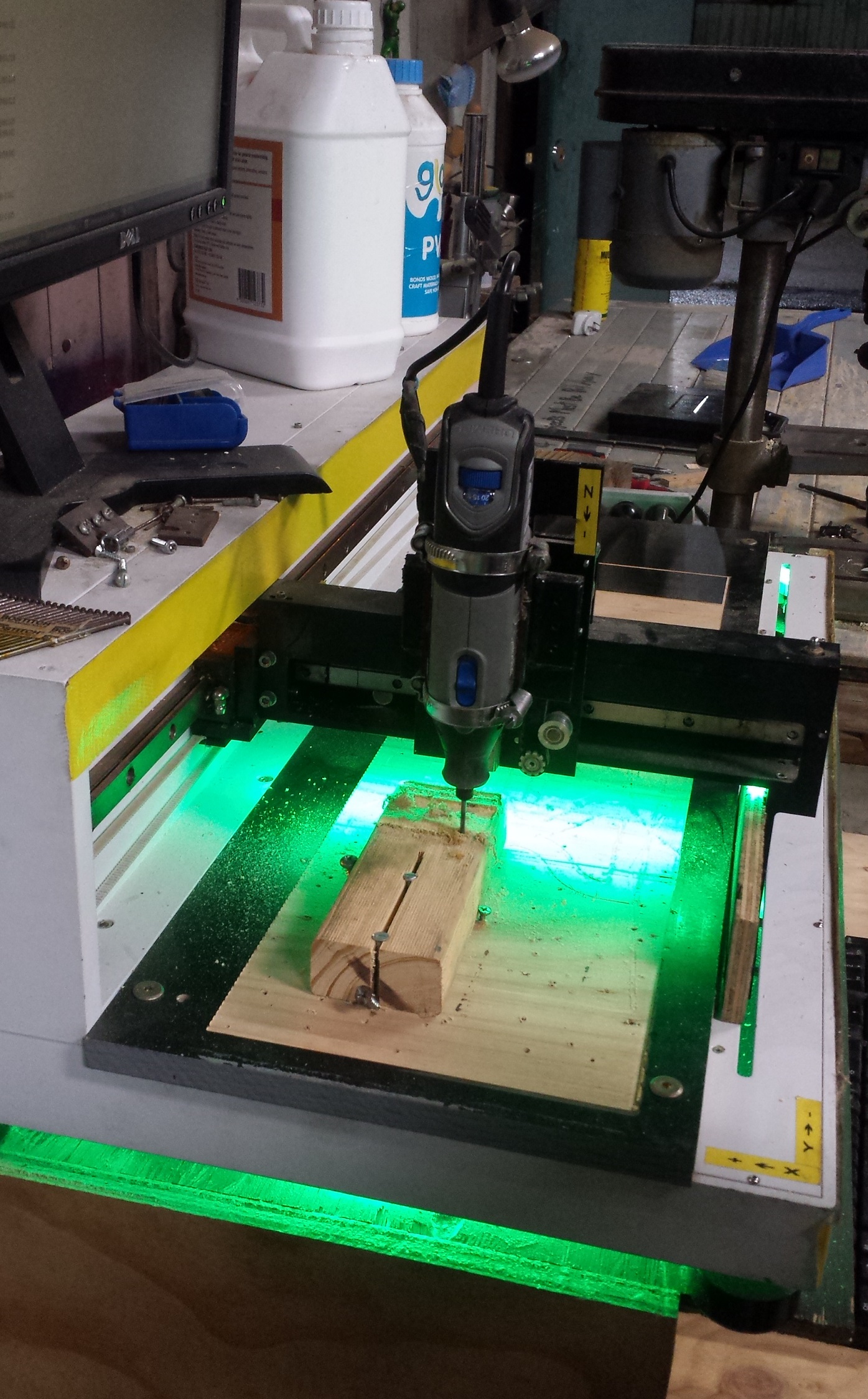

for those inducted on Sven Hanzka’s green and orange(lights) cnc in the wood working room.

Preparing your files

- Import stl from cad or thingyverse into Cut3D or Freemill or similar

- Set units to mm’s

- Orient model home position

- Add material dimentions

- Set speed and feed rates (conservative) [we used 2mm depth 120mm/min with our 3mm cutter]

- Check tool path settings

- Post Processor settings[ G Code mm (*.tap) ]

- Look at the estimated time and weep

The Machine/Computer

- Password is the same as the wifi

- Put your gcode on the desktop (because usb wiggs out sometimes mid route)

- Open program “Universal G Code Sender”

- Set home position on material manually [be sure to remember the orientation of your material in cad and that the y axis is backwards]

- Spool up the motor

- Hover hand over kill switch and click ‘Go’

Success !

Remember this machine is capable of self destricution and personal injury. End mill (fancy drill bit) not supplied. Please only use if inducted. Talk to @Svenska or @Hally or any awesome member to find out how.