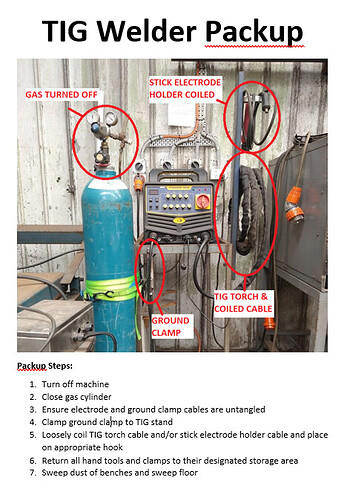

A reoccurring issue in the metalshop is various areas or machines being left unclean with tools left on benches. After the shop rearrangement has been performed this month, I think it would be good to take a picture of each area in the state it should be in after use with a list of cleanup steps. This could be stuck on or near the machine for reference and will remove any excuses for leaving an area unclean. I’ve included an example of what I think should be done in the instance of the TIG welder.

This is a good idea and a extension to what the metal shop policies state in section 2 of the policies. The metal shop policies are up on wiki and also on the back of one of the welding screens in the metal shop.

Yes, this is only an extension to the policy. I think it’s beneficial to have a specific list of steps for people to follow as it reduces ambiguity in the cleaning process.

Just a minor note here from the guy who made that TIG-trolley, and previously worked in a welding shop for a while… although that picture is ok, it was actually designed so that the upper hook should be where the tig-torch-and-cable should be hung-over, and not actually coiled… as when the centre of the cord is/was hung over the upper hook, the torch itself doesn’t/shouldn’t actually reach the floor, ans thus won’t be dragged around on the floor, ans it also reduces the likelyhood that a way-ward torch hits the floor and breaks the ceramic shroud, which is the only really fragile part on the torch head. It was also made so that none of the leads drag on the flor when properly hung. The lower hook/hang point was actually for the earth lead, for a similar reason, (not dragging on floor, easy to reach) The rest of the trolley is also up-high ( above bench height) so knobs are easy to see/read, but also so people across the room can see the equipment is on/off more easily (lights are on, switch is on). i don’t reallt mind how its used, and the above pic seems just about as good… but i thought it worth describing how it was originally thought out…

I see the esp32 System on a Chip camera modules have code for movement activation and image capture followep by upload. In time it would appear to be possible to integrate a member activity image log. Will keep working on a basic pir sensor and sftp to rpi demo system.

How about asking infrastrutuce to look at including a mod to the log out screen such that images of areas swiped need to be clicked? In time actual realtime images could be used.