Purchased this BRASA lamp from IKEA:

Marked out all of the holes to be cut and rough cut them with an angle grinder.

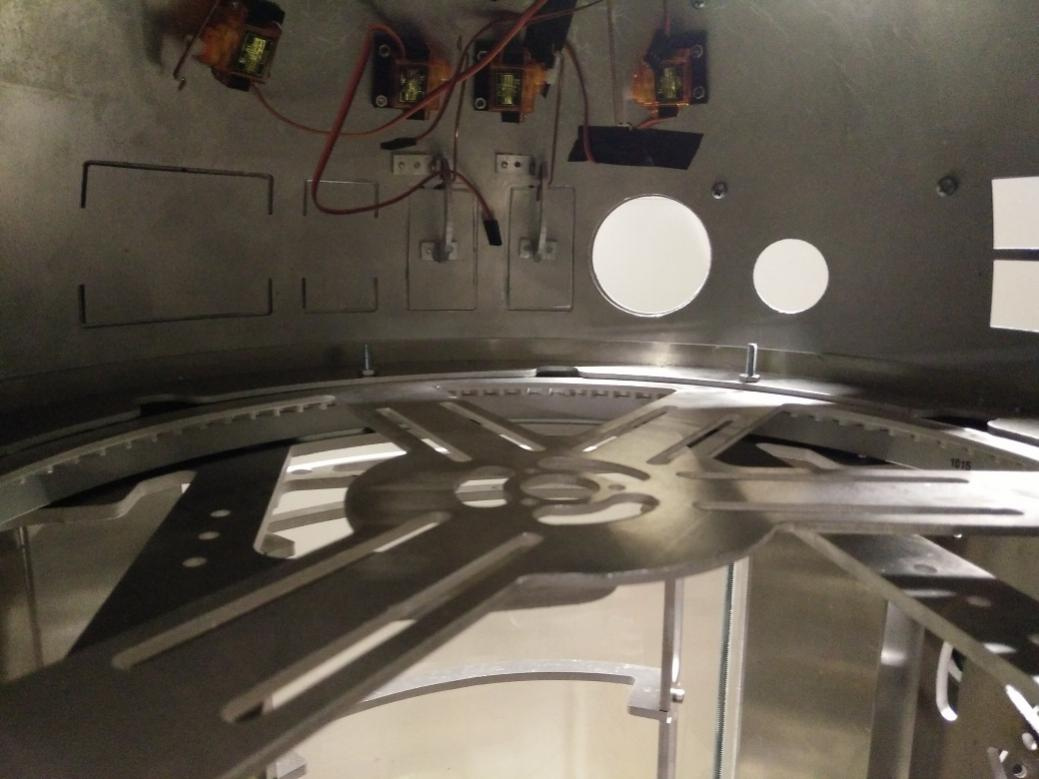

I had painted this but Didn’t like the quality or how it turned out I would have had to buy 2 of these to make one dome, having an inner and outer dome for attaching panels. I had tried 3D printing panels but were not happy with them. I also wanted servo actuated panels and the 3d printed ones were not going to work.

I was also able to control most of the panels using servos. I had fabricated my own hinges using my own design.

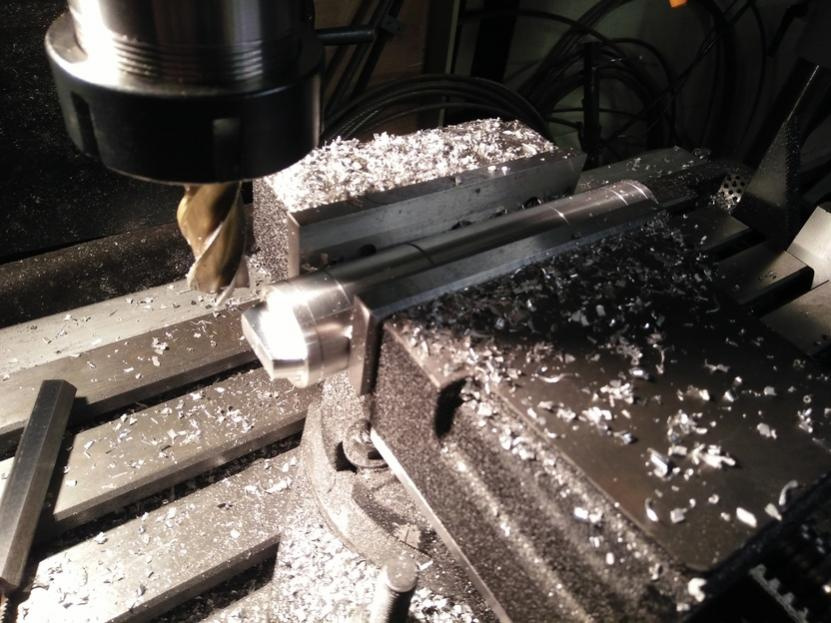

Logic displays: I used the 3D model from the club to create a toolpath for my CNC mill. Once rough cut, I used files to finish the pieces.

I used the TEECES PCB boards and soldered them up. I was a tight fit with the LEDs that I sed but it worked out in the end

They fit perfectly in the dome. I repeat this another time for the second from logic display and yet again for the rear logic display.

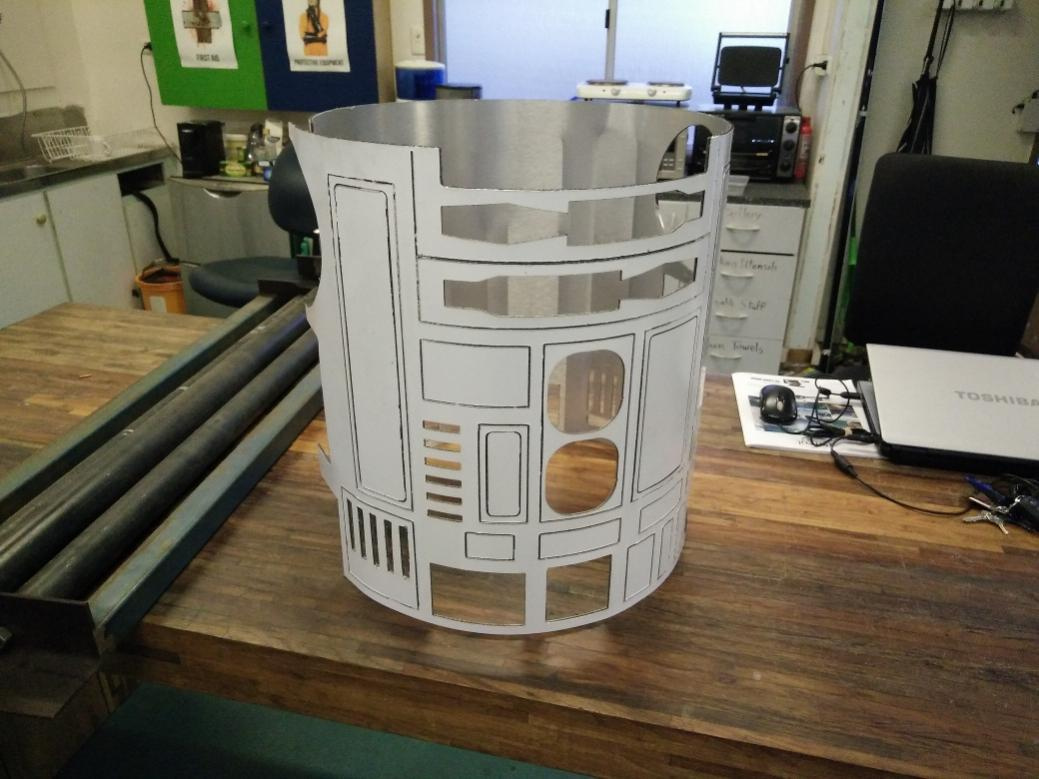

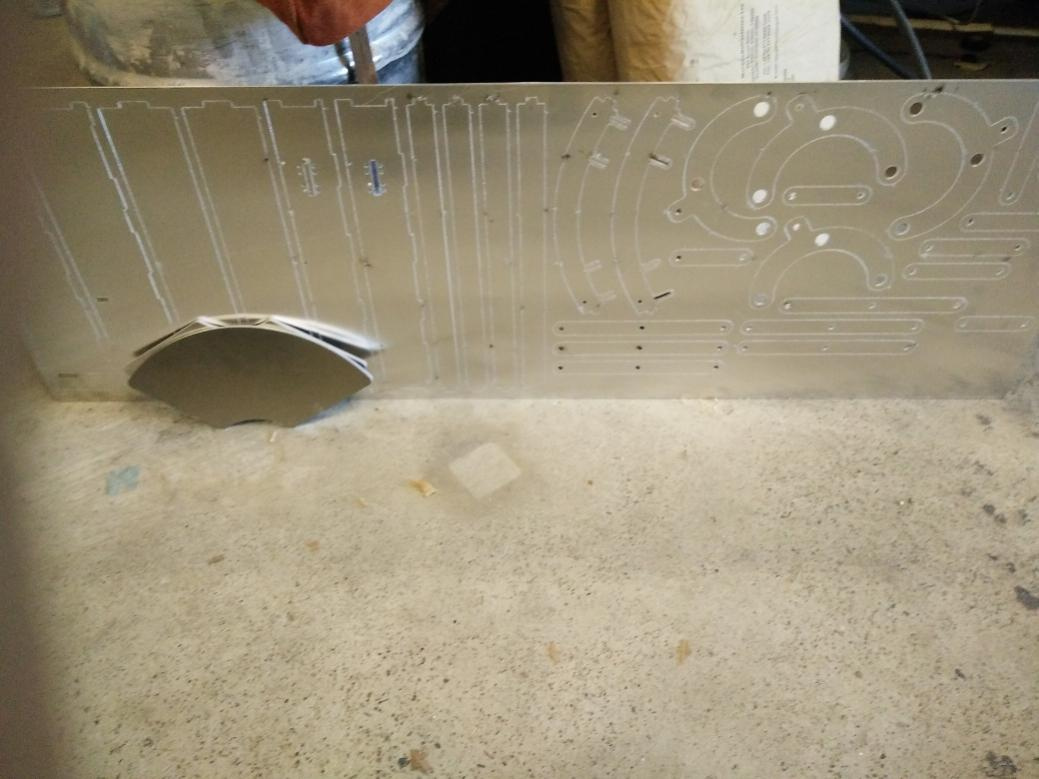

Moving on from the dome for a moment. I began work on the body. Using the CAD drawing of the skin, I used my CNC router to cut out the body skin. I know this is a bit out of order, but I was confident about this step.

I actually had to build a ring roller large enough to accommodate this, But by doing that I have a new tool for the machine shop. Once rolled the skin turned out beautifully.

A huge thanks to Gary from Gary’s Droid factory for providing the plans for the body frame. I had a local person who does laser cutting and waterjetting laser cut my frame panels out of 3mm and 6mm aluminium.

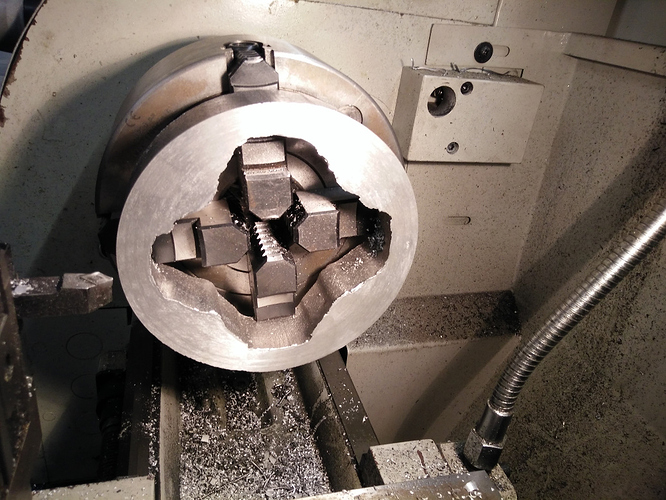

Tapped all of the appropriate holes and the frame went together without much difficulty.

The assembly instructions for attaching the dome to the frame were quite lacking. Mostly because there were multiple different parts for different domes. I finally found a combination that worked.

Success.

Just for grins I put the skin into place. Almost looks like a droid.

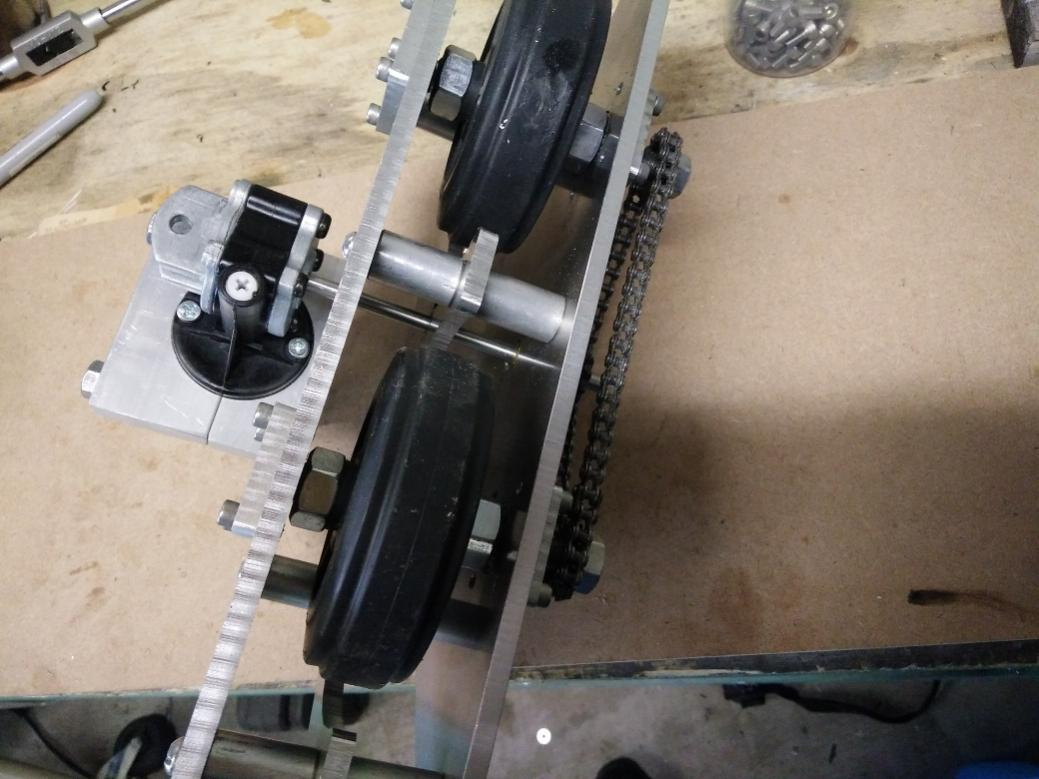

Moving on to the feet. I’ve decided to design the mecanice all myself. I went with a 3 layer 6mm aluminium frame. So more time on the CNC:

The wheels were taken from a rolling cart from Bunnings ( Home depot for you Yanks

Like other designs, I went with the dual wheel chain drive. This is #25 chain

The motor is a 190RPM 12V 90 degree power seat motor. I’ve machined off the acme lead screw and attached the #25 chain sprockets.