Just a quick one.

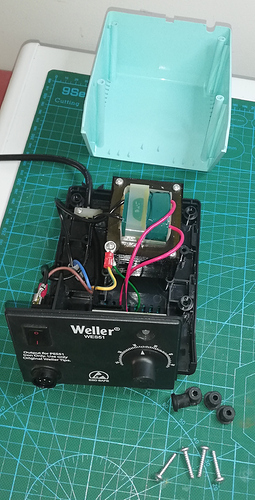

Less of a build log and more of a record of the steps taken to troubleshoot and fix a Weller WES51 that wouldn’t turn on.

I used this station for years with no issues. From what I gathered from various forums, a shorted out tool or plugging in the pen when the power unit is already on can cause this problems. I’m thinking the former, because when I used the pen from the station that wouldn’t turn on, with a working power unit, it too stopped working.

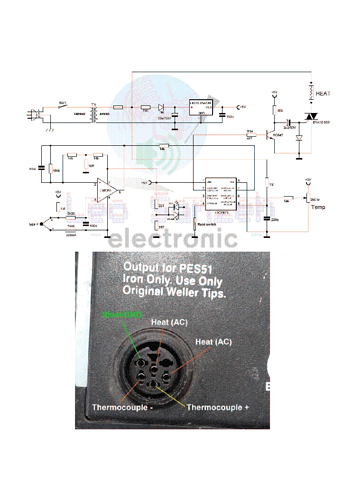

I located a manual and went to the ‘TOOL DOES NOT HEAT’ section.

With line cord unplugged and power switch on, check for approximately 21 ohms at line cord blades (55 ohms for 230V unit)

* Check power switch for continuity in the On position - replace if defective.

* Check line cord for continuity - repair or replace if defective.

* Check transformer primary - replace transformer if defective.

With line cord plugged in and power switch on, check for 24VAC ±10% between pins #2 and #6 of tool receptacle.

* Check transformer secondary for 24VAC ±10% - replace transformer if defective.

* Check wiring to printed circuit board assembly - repair or replace if defective.

* Replace printed circuit board assembly.

Right above, there is an angry looking symbol and ‘WARNING: AC line voltage is present inside power unit even when power switch is off. Refer service to qualified personnel.’

I’m the proper amount of risk averse, so I’m not going to go messing around with lethal electricity. I asked the electrician that came around to fix our meter if there was any troubleshooting I could do as an unqualified person.

He told me that I could do every step except for:

*'Check transformer secondary for 24VAC ±10% - replace transformer if defective.'*

… and that the reason is: mains voltage needs to have two layers of insulation, or one layer if it is accessible by a tool. So after opening the case with a screwdriver (a tool) there will be wires inside that carry mains that have only one layer of insulation, so you can’t go near it.

So starting at the top of the checklist:

With line cord unplugged and power switch on, check for approximately 21 ohms at line cord blades (55 ohms for 230V unit)

… and I only get ~33Ω

The next step is to:

Check power switch for continuity in the 'On' position - replace if defective.

… but it makes more sense to do the:

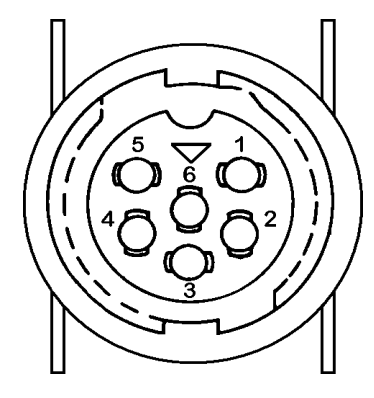

With line cord plugged in and power switch on, check for 24VAC ±10% between pins #2 and #6 of tool receptacle.

… while the power unit is still assembled.

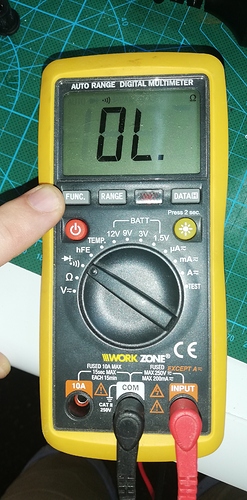

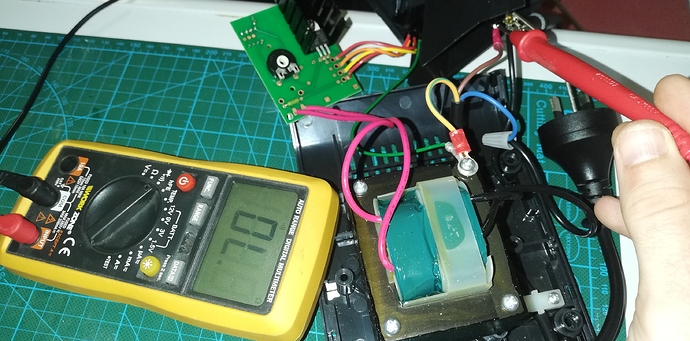

Set the multimeter to ‘auto voltage’ and check the voltage between #2 and #6

… and I get ~2 volts, which is not what I’m after.

Set the multimeter to beep at me if there is continuity so I can check the switch continuity:

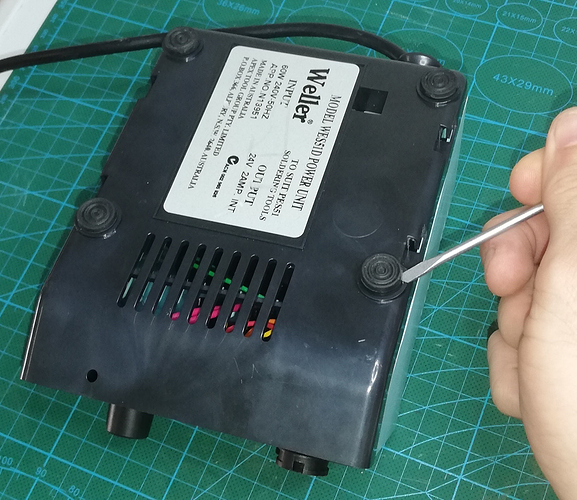

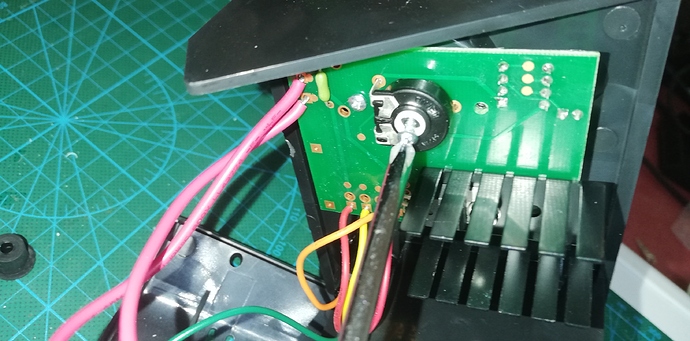

To get to the switch terminals though, I’ll need to take apart the case:

With access to the switch terminals I can test for continuity.

It reads open loop in the picture, but the switch did make the multi-meter beep, I was just too fast taking the picture.

To be continued…