Automated Dust Collection

As part of the wood shop team’s upcoming plan (yet to be voted on) we plan to start automating the blast gates and dust control in the wood shop. Before we get too far though, we wanted to give an overview of the project so that people could give some input. Specifically, we would like feedback on what people want to get out of the automated dust collection and input into how to integrate it within the wider HSBNE infrastructure. Of course, other feedback and technical design suggestions/review is more than welcome.

After feedback and working out the exact technical solution I’ll put together a bill of materials and budget to be voted on at a general meeting.

The Problem

A critical part of keeping the wood shop clean and the air breathable is the dust extraction system. Right now, blast gates (valves) are fitted to each machine that members must manually open and close to control the flow of air. Members must also manually turn on the dust extractor. There are several problems with this manual system.

- People forget to open the blast gate when they are using the machine

- People forget to close blast gates when they are done with a machine, reducing the effectiveness of dust collection throughout the system.

- People forget to turn on the dust extractor.

- Several blast gates are difficult to reach. This makes the system inaccessible for many and disincentives its use.

Success Criteria

In order to solve these problems, a system must be developed that meets the following the criteria:

- Blast gates must be easily operable from where an operator would stand to use a machine.

- Blast gates on all other machines should be able to be closed while standing at any given machine.

- The dust extractor should be turned on automatically whenever a blast gate is opened.

- The dust collector should be able to be switched on and off manually.

- When the dust extractor is turned off manually or has been off for more than 1 hour, all the blast gates should be closed.

There are also a number of requirements stemming from technical considerations, mostly to avoid damaging or wearing out the dust extractor.

- The dust extractor should never run with all blast gates closed. To avoid this, at least one blast gate should be open at all times.

- The dust extractor should not be cycled on and off rapidly. When a blast gate is opened the collector should operate continuously for at least 10 minutes (in anticipation that it will be needed again soon), even if all blast gates are closed. During this 10 minute period, the dust extractor can be switched off manually.

In expectation of future interlock designs featuring current sensing (to tell if the machine is currently in use):

- The system must contain a mechanism by which a device measuring current use on a machine can be used to open and close a blast gate.

The Solution

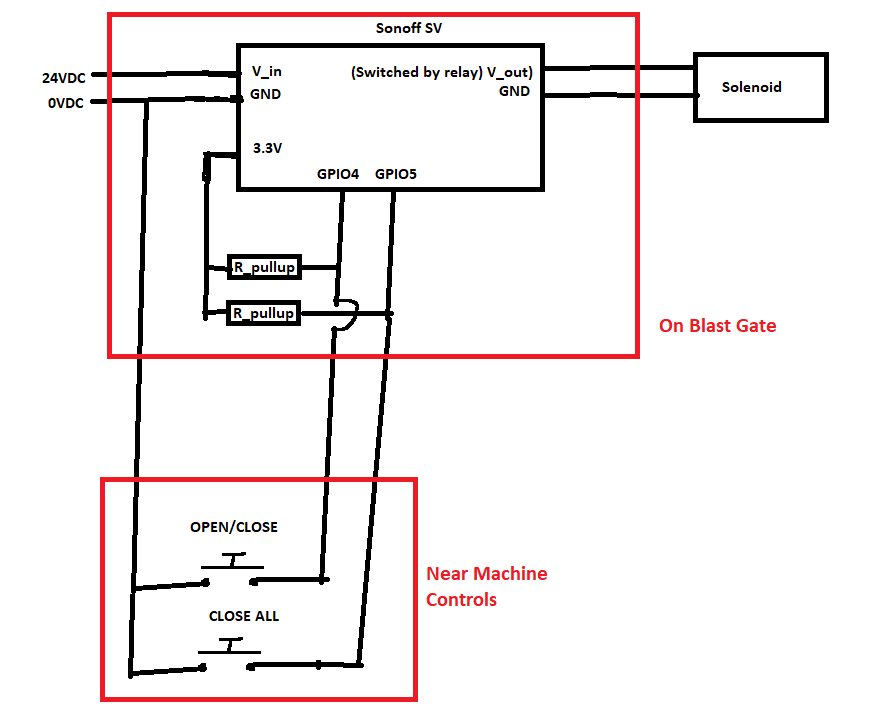

Currently compressed air lines and 24VDC power is already run to each blast gate. Each blast gate is fitted with a pneumatic cylinder which can open or close the gate when paired with a solenoid. To control each solenoid a Sonoff SV will be used (similar to an Arduino). The Sonoff SV is an ESP8266 board with integrated power circuitry (5-24VDC), relay (for triggering the solenoids), and WiFi. The user interface will consist of two momentary push buttons; one to open and close the blast gate and the other to close all other blast gates. The remaining automation will be handled in code.

Note that the pneumatic cylinders fitted to the blast gates will make it impossible to manually open/close the blast gates.

The user interface would look like this, made up of two momentary push buttons.

The buttons do what they say. The green one has the additional function of turning on the dust collector if it is not on already.

Technical Details

The full technical details have not been fully fleshed out yet as I want to give the opportunity for people to review the plan before committing to it.

The Code

As far as is practical the Sonoff SVs will be kept ‘dumb’ and will have limited internal logic. To this end, the MQTT protocol will be used to communicate with a central controller service which will execute the core logic of the system and direct the peripherals (Sonoffs and dust extractor) as appropriate. Such a system could be updated later if interlocks gain current sensing abilities.

As a rough layout for the MQTT design, each Sonoff (with its own UID) will engage with the following topics:

-

Subscribe to “DustCollection/[UID]/Commands” and open/close it’s associated gate when the controller publishes to the topic.

-

Publish to “DustCollection/[UID]/State” to inform the controller when the gate is opened/closed (regardless of if the it was commanded to by the controller or by pushing the button). This topic will also be used when the ‘close all other blast gates button’ is pressed.

The Electrical Design

Excuse the MS Paint.

Other

As a further stretch goal, blast gates may be added that cut off entire branches of the system when they are not in use. This would improve the performance of the system.