I talked to @denominator, he’s got a ute with racks and he’ll pick it up for us in the next couple of days.

Hi Guys, have a look at what I rote on the “Help / suggestions needed for potential wearable tech workoshop on the 25th of October” topic. So how does a dedicated building the Robot day on the 25th sound! Karl will you be around ? the more people we can get coming along building and showing visitors what we do the better…

Sounds like a bad idea to change it to a robot building workshop. Too many cooks and stuff. You should keep it a s a personal little workshop for wearable stuff. But thats just my opinion I would be there but its my Bday.

My intention is not to get visitors actually building the robot but to showcase the process and the space before we focus on making some decorations for the robot as well as some wearable stuff for the participants.

Oh and Happy Birthday in advance

So I guess this means you will be coming along

I’m going to build when I can, I won’t be doing anything tomorrow and it should be mostly done by next saturday. It sounded like a good idea when I spoke to you on the phone but when I thought about it I realised theres not going to be anything to look at other than the finished pieces. It’ll be a few long days of someone standing at a saw doing cut after cut after cut and someone on a jig doing weld after weld after weld, neither of which of which are particularly good spectator sports. They do make excelent photos though. Spectators also tend to wreak havoc on work flow.

But that said, if you can find people that want to walk through an active work site to watch someone cut and weld steel for shits and giggles, bring them on down, so long as they realise what they’re in for.

I can be there next Saturday, and probably some evenings in between. I can’t weld (yet, though it’s something I want to learn), happy to help out any way I can, even if it is endless drop-sawing metal…

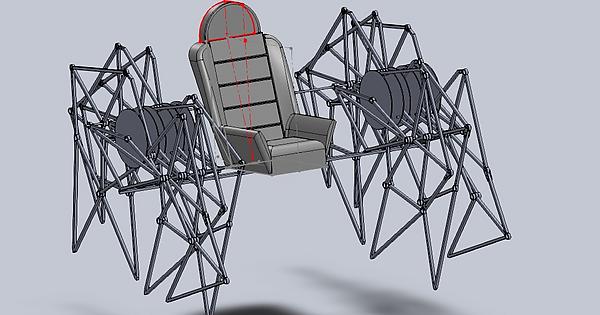

This is basically what it’ll look like.

http://s000.tinyupload.com/index.php?file_id=33045617727442516704

Thats a link to the solidworks .asm.

Each joint with more than 2 intersecting members is a few pieces of 26NB pipe with a 6000 bearing inside, secured with a grub screw. bearings are separated on the bolt with pieces of 10NB pipe.

Each joint with only 2 members is basically the same thing but with plates on the sides.

Hey Karl,

This is a pretty large job, make sure to ask for help wherever needed  Myself and many others will gladly assist you wherever we can

Myself and many others will gladly assist you wherever we can

First, can I just say I love this thread to bits. It reminds me of the glory days of the mailing list.

Second, if you want to figure out a colour scheme and buy the paint out of the budget, I’ll happily contribute by airbrushing all the parts. If time permits I’ll also help weld if need be.

Update from tonight’s meeting: 13 for Karl Richardson to be project manager for the parade robot, 0 against. The project manager is able to spend up to the $2500 budget, without further approval from the group. The project manager must provide receipts and/or invoices to the Treasurer.

Oh yeah, there was a meeting on tuesday. Whoops. A little update from me, I spent the last 3-4 days working on a uni project that fell in a steaming pile of shit, so that was nice. I’ll be working on this from now on. I think I goofed on the steel a little, I ordered 15mm SHS, I think 25mm will bet better suited in this situation, the small stuff I got for a good price so I’ll keep it as I can think of many other little projects to use it on in the future, such as a welding class and shelving.

I won’t be able to make it to the space on Saturday as my centerlink has been shitcanned, so work gets bumped up a level of importance. I’m going to finish this first though.

I also goofed on the saw I bought. Its outside the safe RPM rating for what I wanted to use it for. I’ll relist it on gumtree and get our money back on that one. I’m looking at a band saw for us instead which wont be much more expensive. Looks as though we can have one for under $400, so ill be looking into that today.

Thanks For The update Karl.  I hope the larger size steel is not to heavy though! If anything doesn’t work properly or in case of failure I would prefer the robot to be on the lighter side of the scale.

I hope the larger size steel is not to heavy though! If anything doesn’t work properly or in case of failure I would prefer the robot to be on the lighter side of the scale.

While it is cool, the robot does not need to be strong enough to carry a full grown man, so I’m not sure about getting the larger and heavier stuff.

I’m free all day Sunday for any cutting/construction/general labour. Also someone mentioned the red drop saw burnt out? I had a quick peek at it on Tuesday night and it still turns freely so perhaps it’s salvageable? I’ll have a closer look tonight. Also I noticed the handle on the new drop saw was broken, I’ll have a look at patching that up too for its resale.

Update: Today shit gets real as a motherfucker. My schedule is clear this week and now the process of pounding this steel into submission begins with furious gusto! Today will most likely be fiddly fab work, but by tomorrow I should be able to farm out some cutting/grinding/welding/machining to whoever is willing and able. So if you’re keen to get stuck into this, ring me on 0449 147 030.

Update 2: Frames and legs are all welded up, tomorrow I start on a crank, then it moves!

We’re having big issues with the motor controller, the ones we ordered keep letting the magic smoke out as they are sans such extravagant extras such as protection diodes. What we need is a beefy dual H-bridge with PWM control and all that jazz. Motors draw <20A (probably). Please put your feelers out and see what we can track down.

Awesome

I’ll focus on finding an alternative for our motor controller first thing tomorrow morning.

Cheers

I might have something at work you could borrow would have to check when I get in.