Note to people who have arrived here via Google: if you own one of these Rowe Popcorn Machines, I’d love to get in contact with you! We’re missing some parts in our machine and would love it if you could measure some parts for us, or even just take a few reference photos. And I’m happy to offer advice about some of the things I’ve learned about this machine too. Sign up for an account on this forum (it’s free), click my username & send me a Private Message and I’ll hook you up with my email & phone number.

For those new members who don’t know what I do around the space, I’m the guy who does the majority of work stocking our Drinks Machines with all sorts of fancy flavours. And for those people who don’t know me personally outside the space, I love popcorn. Well I was looking at some things online recently, and… long story short, I now own an automatic popcorn popping & vending machine.

(I have absolutely zero regrets making this purchase)

The machine in question is an automatic popcorn popper/cooker and vending machine, a Model 290 “Silver Screen” unit made by Rowe International. Getting it to the space was a bit tricky, because it seems I underestimated my purchase - this thing’s 6 feet tall and weighs around 230 kilos! I’d like to give a huge shout-out to @Svenska for assisting me with the pickup with his ute, and @jace as well for being another pair of hands unloading it into the space.

(fun fact - it’s a VERY tight fit, but a ute’s trailer will juuuuust fit through our front doors)

So, what’s the plan? To get this machine running and serving fresh hot popcorn at the space!  To do this, a few things need to happen. If you want to help out, depending on the task feel free to either just jump in or ask me for direction!

To do this, a few things need to happen. If you want to help out, depending on the task feel free to either just jump in or ask me for direction!

- Cleaning - clean the machine of the bulk of the dirt, dust, grease, grime, and whatever other gunk is inside it. Wanna help out? The exterior of the machine still needs cleaning! The right side and the rear in particular are filthy, and you’ll go through more than one bucket of hot disinfecting water cleaning them out. Also the very bottom of the machine needs to be cleaned with a scraper or paper towels or something, because it will just destroy chux/sponges with single wipes… maybe put some oven cleaner on it or something super strong. Basically the aim for this step is to make it such that your hands don’t get dirty while working on the machine, aka to remove any dust that would be a health hazard when just working on the machine (not when it’s operating), as well as anything that could be fire hazard to the heating elements etc.

- Electrical work - replace the main power cord (it’s been crushed and I don’t trust it), clean a bunch of the connectors, reconnect the transformer and the line conditioner, check some things individually. Check as many things as we can think of before we apply power for the first time. In particular anything on the bottom of the machine, and the flavouring metering dispensers.

- Sterilising - this time, the aim is to sterilise all important surfaces to be food safe. You can probably see how this is a separate step from the first one - this one calls for sterilisation, while the first step calls for just general cleanliness.

- Software/hardware hacks - find some guides or manuals on this machine, if we can. Reprogram it, if at all possible. Hack together bypass systems for whatever is necessary. Build a new coin holding metal container, a new grill (or floor) for the popcorn container to sit on in the collection area, walls/ceiling for the collection area, and bypasses for any systems we can’t use (like perhaps the cup vending part or the flavouring metering dispensers or the flavouring mixers). This also includes stuff like changing all the settings to be correct for what we want, notablystuff like making sure the auger dispenses the right amount of kernels per serve, since whatever it’s set at right now is likely wrong as there’s such variety between kernels.

- Acquire supplies - I have 100 paper popcorn bags as a test that have already arrived and I have 3 kilos of variously flavoured salts coming in the mail. This machine uses liquid oils for flavours so I may not be able to use these salts, I have to see if I can DIY mix them up or not. I’ll also need a few kilos of raw kernels designed for popping - so far it looks like the cheapest price is the small 300-400g bags at my local supermarket.

- Profit! - well, once it’s paid me back that is. This is a personal purchase of mine, not a piece of equipment owned by the space. This way we’ve avoided any issues about buying something when we’re short of funds, getting reimbursement for something that was bought at an auction without a membership vote etc, and most importantly it gives me a big dangling carrot as an incentive to get this machine running asap. Once it’s earned enough that I’ve covered costs, then the space will be getting profits and possibly even just outright donating the machine to the space too. While I’m at it, I’m totally happy to relocate this machine somewhere else while I’m working on it, or others can do that themselves if it’s in the way and you need it moved right that second - I recommend the pallet jack from a 45’ angle.

If all else fails, this purchase wasn’t a complete loss because the coin counter inside this popcorn vending machine (a CashFlow 560 24V) is close to a drop-in replacement for the one in the Vigo drinks machine, except newer and capable of different prices per line. Those are many hundreds of dollars each, even second-hand, so this specific machine still has value to HSBNE.

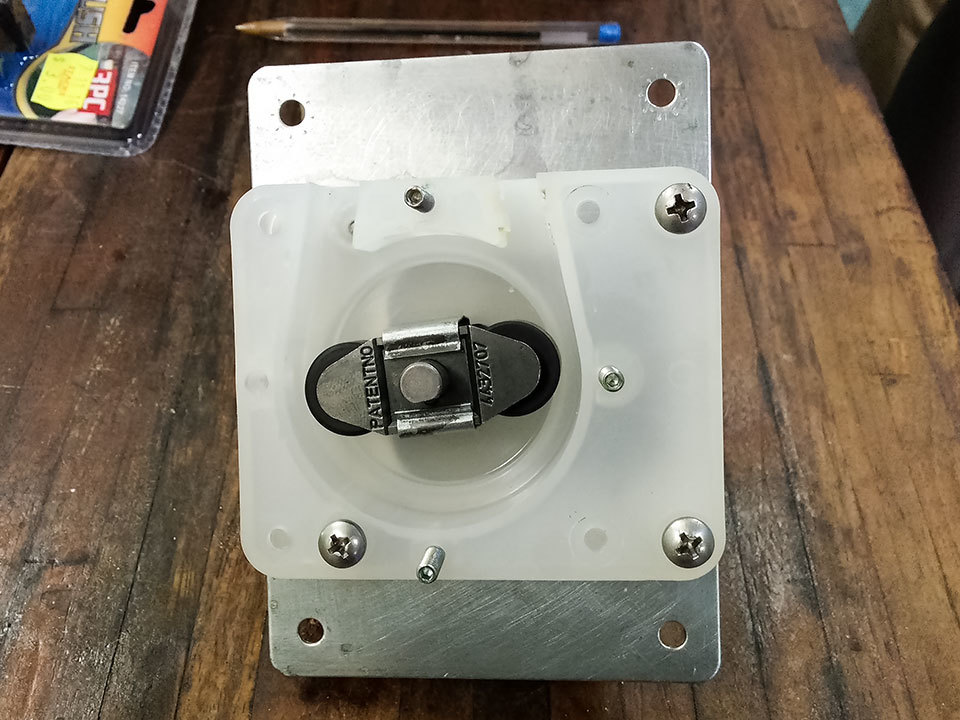

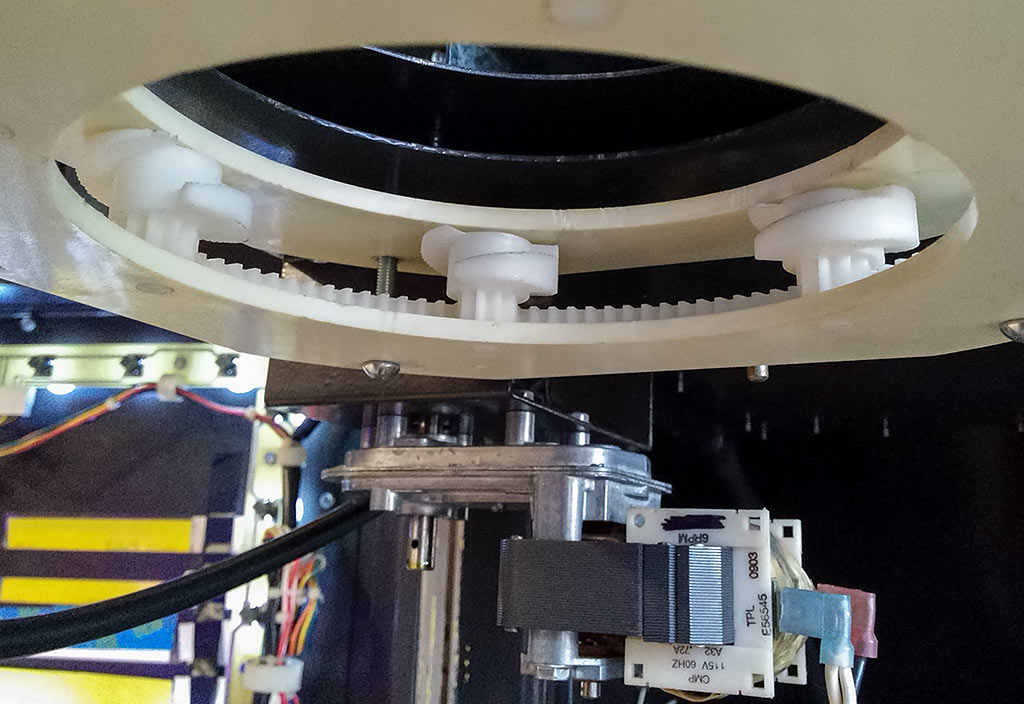

I’ll be posting plenty of photos of the popcorn machine’s insides and other details soon, but for now, if you’re curious about how this machine works I totally recommend you check out its patent. Our popcorn machine is an almost identical copy of the machine pictured in that patent, which features some handy exploded views, cutaways, sectional diagrams, and explanations of how everything works.

). The good news is that I’ve been able to reverse this process to “refresh” the kernels through the clever application of large quantities of silica gel. Based upon my measurements, I’ve now increased the popped kernel volume by a good 30-40%! So much so that I’ve had to adjust some values inside the machine to reduce the amount of spillage from the cups overflowing with popped popcorn. To help prevent this in the future I’m reducing the amount of kernels stored in the hopper as much as I can, plus there’s now a 100g silica gel packet placed in the hopper (and I’ll monitor that packet’s weight to measure the kernel moisture content), and I’ve attempted to create a bit more of an airtight seal on the lid (but not 100% air tight because that would just create more problems as the air pressure varies). We’ll see how well this works in the long-term.

). The good news is that I’ve been able to reverse this process to “refresh” the kernels through the clever application of large quantities of silica gel. Based upon my measurements, I’ve now increased the popped kernel volume by a good 30-40%! So much so that I’ve had to adjust some values inside the machine to reduce the amount of spillage from the cups overflowing with popped popcorn. To help prevent this in the future I’m reducing the amount of kernels stored in the hopper as much as I can, plus there’s now a 100g silica gel packet placed in the hopper (and I’ll monitor that packet’s weight to measure the kernel moisture content), and I’ve attempted to create a bit more of an airtight seal on the lid (but not 100% air tight because that would just create more problems as the air pressure varies). We’ll see how well this works in the long-term.