Here’s the state of affairs!

- Maz is donating us a tablet for the interface

- I’m going to ask @nogthree for an iBoard

- I’m going to get some spare rfid equipment off Wizard

- I’ve started some of the software stack

- On saturday I proved my hinge concept to Jimmy, which consists of laser cutting the doors.

- While this method works pretty great, I think there’s a bit of a room for improvement, see below.

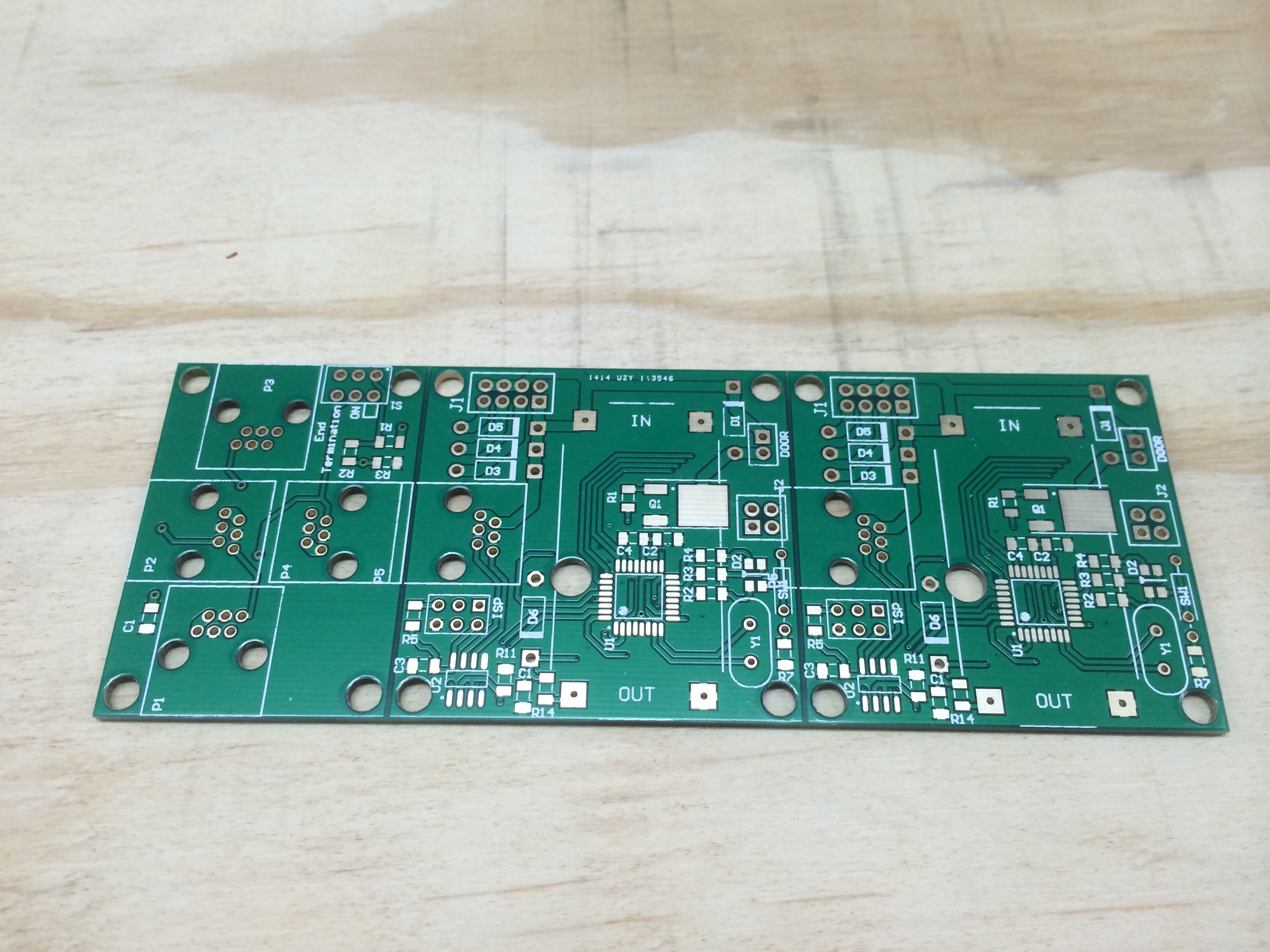

- We’re building boxes out of 6mm AA grade hardwood marine ply

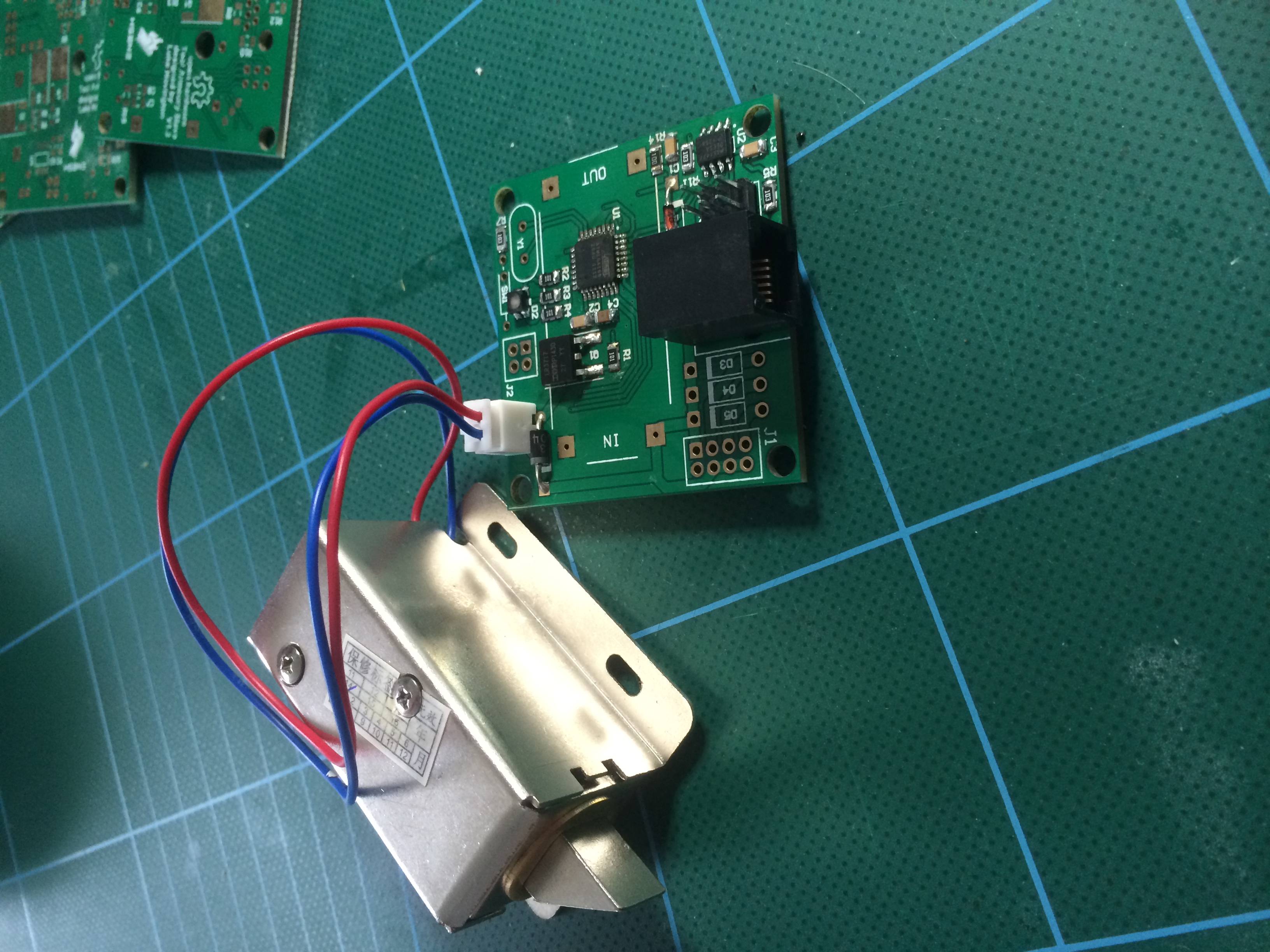

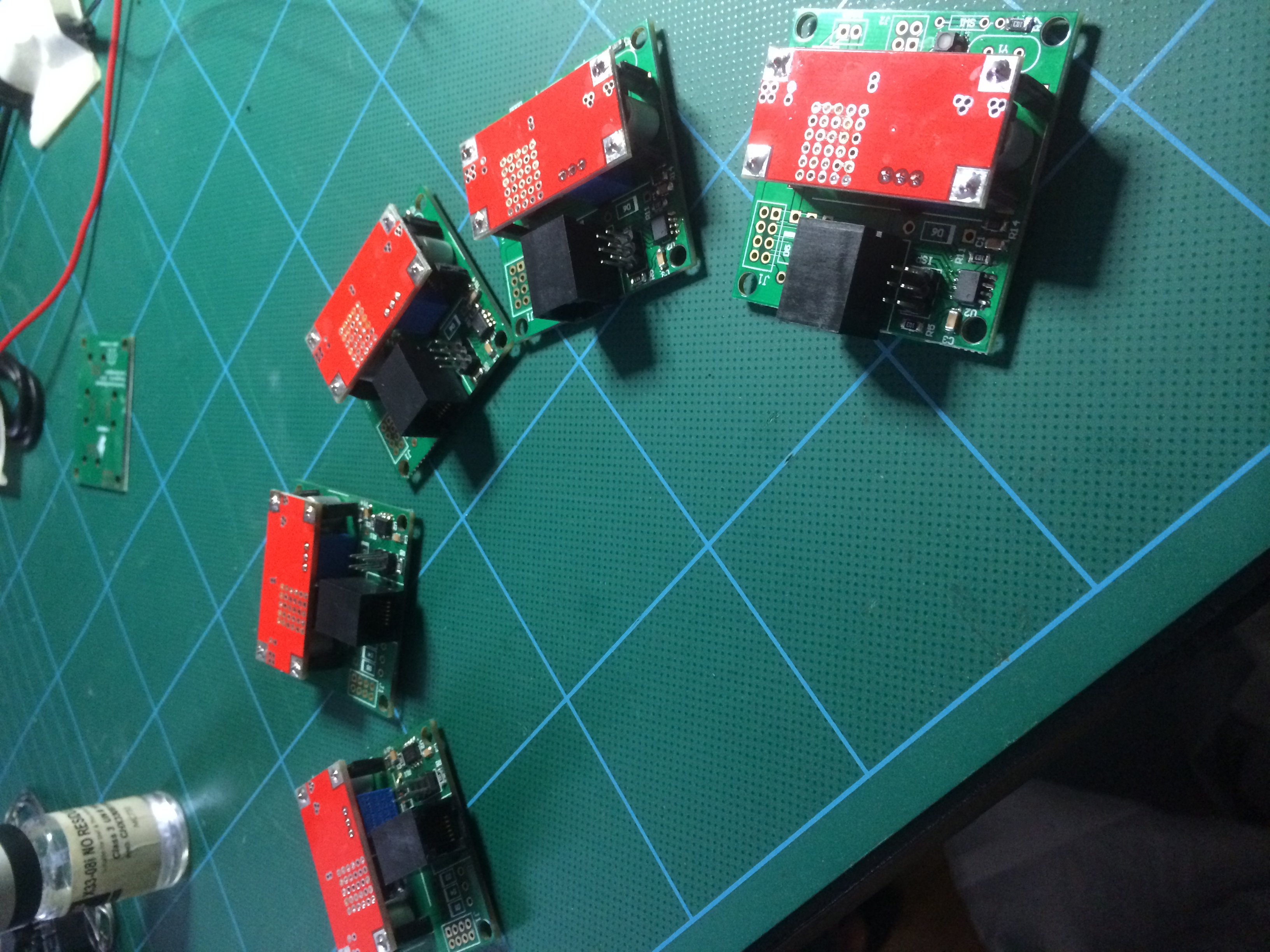

- We’re affixing the control circuit and relay to the door.

Things yet to be figured out

- I need to knock up a basic 3d printed or laser cut design to hold electronics and such.

- We might need to find some appropriate drawer pulls at bunnings.

Blocking further progress

Both Luke and I are flat broke at the moment. If you can chip us some money to keep this rolling, come talk to us. We’re pretty much stalled until we get more funds.

The Hinge Problem

So I did a quick design on the laser on friday that is essentially the square door with some tabby bits on it to pin into the top/bottom of the box. It works great, but its not amazingly hard wearing. I was thinking about reinforcing with some other materials and some washers, but going down that path I thought, why not a bit of round alu stock with a slot in it? its certainly cheap enough, the ‘hard part’ is milling a slot in such stuff, which is just waiting on the mill to get going. but that would work amazingly, and be extremely hardy, not have any wastage. It’s slightly trickier manufacturing wise, but its probably the simplest mill operation possible.

Why not standard hinges? If you havent been following along with us, hinges are usually expensive, and they’re just flat out tricky to get right in this situation and our parameters for stacking.

So, I’m currently advocating either laser cut panels, or doing a slotted alu solution.

Software Stack

Current stack will be a L*MP implementation on the android tablet, running in a kiosk mode. The iBoard and Tablet will communicate via HTTP, the iBoard and IGOR’s will communicate via RS485.

Implementation Notes

IGOR’s are dumb, their protocol is literally [{output: <n>, mode: <q>, value: <v>},...]. This allows only flashing of the iBoard in order to upgrade functionality.

User Journeys

Taking a tool:

- User uses rfid to activate

- User selects box with coordinate panel

- Relevant box opens (unless induction locked (v2 release probably))

- User is now responsible for tool(s)

Reporting breakage:

- User takes tool, notices problem,

- User returns to panel, notes they have a broken tool, picks the tool thats broken.

- User selects either broken in my use, or checked out broken. Both options email user, exec. Latter emails last 3 users as well.

Returning tools:

- User swipes, is displayed a list of currently checked out tools.

- User selects one at a time to return tools to their correct boxes.

TL;DR

We’re super close, but we’re lacking in funds. If you can pitch in to help us get this done, come talk to us. All the details are more or less worked out, with the right tools and the right materials, we could knock this out in a day.